New! Check out Board view Check out the new Board view Organize and track your social content ideas with the new Board view. Learn more

The 5 Whys Process We Use to Understand the Root of Any Problem

Former Director of People @ Buffer

Sometimes things don’t go according to plan. Tools break, wires get crossed, the best-laid plans fall apart.

And on those occasions, it helps to know exactly what happened—so it doesn’t happen again.

Moments like these are when we at Buffer turn to a simple but remarkably effective process: The 5 Whys.

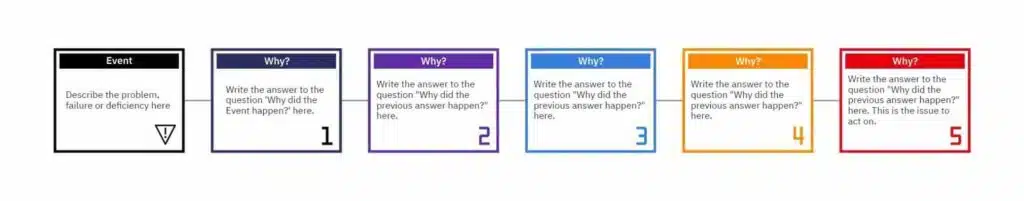

It’s just as it sounds: A discussion of the unexpected event or challenge that follows one train of thought to its logical conclusion by asking “Why?” five times to get to the root of what happened.

But it’s also a lot deeper than that, too. Let’s take a look at the origin and history of this unique process, and I’ll tell you a bit about how it works for us on our remote team at Buffer—and how it could work for you, too.

The origin of the 5 Whys

The 5 Whys technique was developed and fine-tuned within the Toyota Motor Corporation as a critical component of its problem-solving training.

Taiichi Ohno, the architect of the Toyota Production System in the 1950s, describes the method in his book Toyota Production System: Beyond Large-Scale Production as “the basis of Toyota’s scientific approach . . . by repeating why five times, the nature of the problem as well as its solution becomes clear.”

Ohno encouraged his team to dig into each problem that arose until they found the root cause. “Observe the production floor without preconceptions,” he would advise. “Ask ‘why’ five times about every matter.”

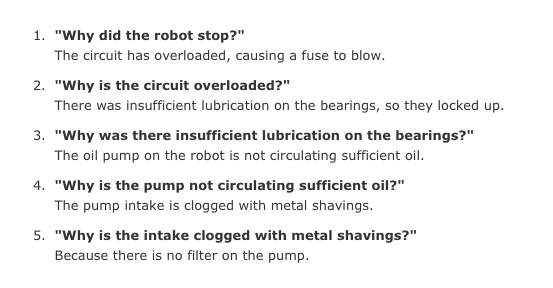

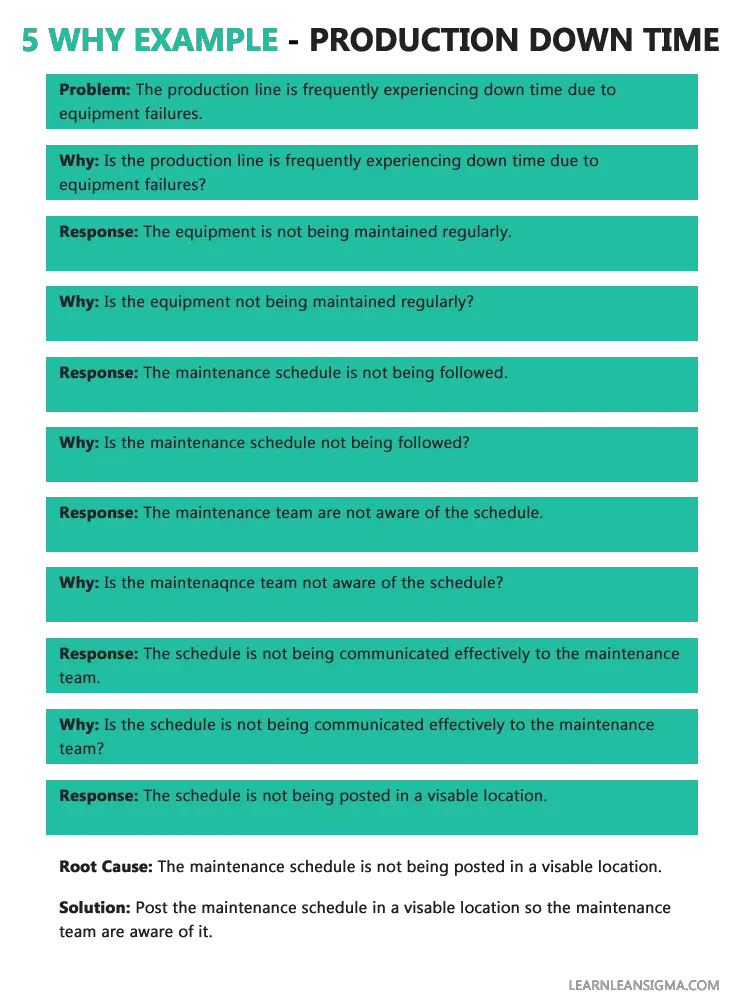

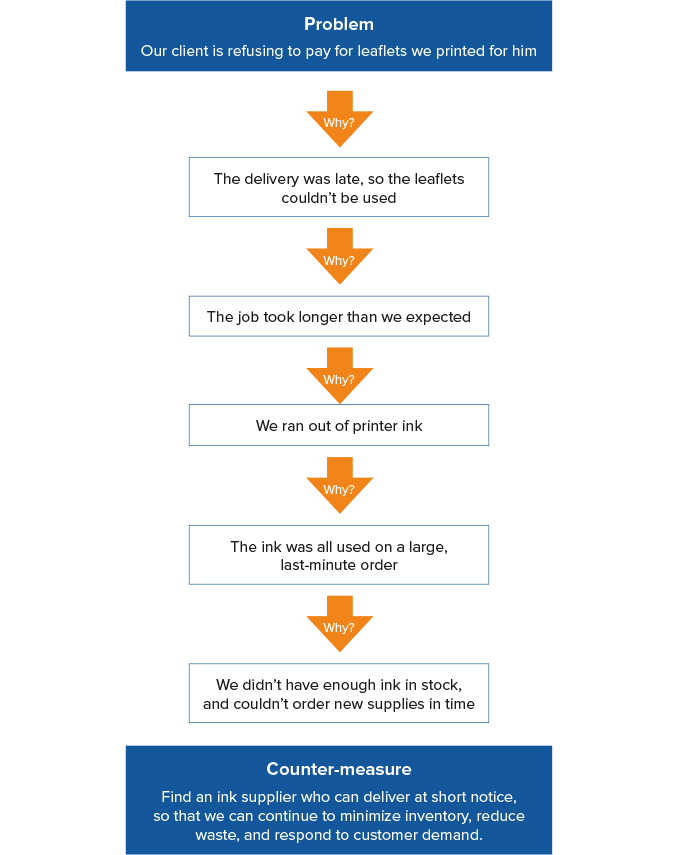

Here’s an example Toyota offers of a potential 5 Whys that might be used at one of their plants.

Today, the method is used far beyond Toyota, and it’s particularly popular in the world of lean development. A lot of what we know at Buffer in implementing the 5 Whys has come from The Lean Startup ‘s Eric Ries, who does an amazing job describing the 5 Why’s in these two posts.

How the 5 Whys process works

At our startup, we perform a “5 Whys” after something unexpected has occurred—and that means we perform them a lot! We keep a “5 Whys” folder in our team’s Dropbox Paper account, and the folder has 20+ notes files and counting (not to mention the 5 Whys docs that might not be categorized into the folder). ‘Fires’ of various sizes are inevitable—and probably the only constant in the life of a startup.

We’ve held these discussions in every facet of Buffer, from engineering to happiness to marketing and more, and the same process holds true no matter whether the problem is technical or more human-based. Here’s how Eric Ries explains:

“Five Whys involves holding meetings immediately following the resolution of problems the company is facing. These problems can be anything: development mistakes, site outages, marketing program failures, or even internal missed schedules. Any time something unexpected happens, we could do some root cause analysis.”

It’s important to note that the purpose of the 5 whys isn’t to place blame , but rather to uncover the root cause of why something unexpected occurred. Additionally, it helps a team create small, incremental steps so that the same issue doesn’t happen again (to anyone).

Tweet this ?

At Buffer, the habit of conducting 5 Whys originated from the engineering team. Here’s how our former CTO Sunil Sadasivan describes the changes that have resulted from making these a routine part of how we operate:

“What I really like about this is that it lets us worry about issues when they happen, and it helps us work towards ensuring they won’t happen again. At the same time, it lets us not have to worry about issues that haven’t happened. I now trust if something comes up that we didn’t foresee, we’ll conduct a 5 whys and learn from it. We let the 5 whys dictate what documentation we need in place or adjustments to make in our on-boarding process.”

Want to try it for yourself?

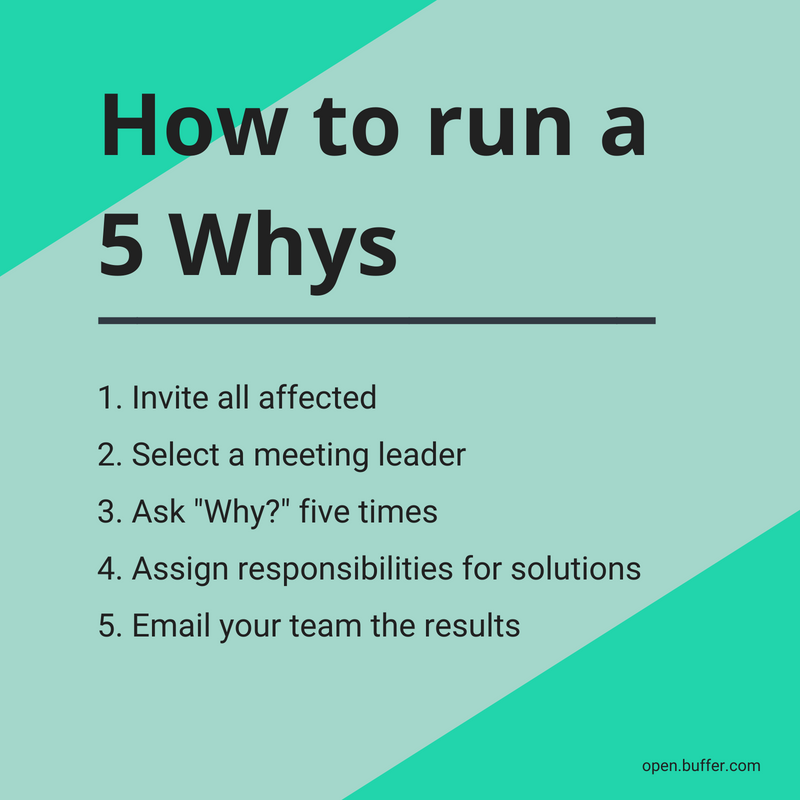

The 5 main steps to the the 5 Whys

Step 1: Invite anyone affected by the issue

As soon as the problem or situation is identified (and all immediate concerns are dealt with), invite anyone at all on the team who was affected or noticed the issue to be involved in a 5 Whys meeting. As a remote team , we hold ours via Zoom.

Step 2: Select a 5 Whys master for the meeting

The 5 Whys master will lead the discussion, ask the 5 whys, and assign responsibility for the solutions the group comes up with. The rest of those involved will answer those questions and discuss.

In our experience, anyone can be a 5 Whys master — there are no special qualifications, and it doesn’t have to be the leader of the project or the originator of the issue. We’ve also found that it’s a good idea for the 5 Whys master to take notes for the meeting, unless he or she would like to assign someone else to this.

Step 3: Ask “why” five times

Dig at least five levels deep into the issue with five levels of “whys.” This seems like the simplest part but can in fact get a bit tricky! Getting the right question to start with, the first why, seems to be the key.

When we conduct our 5 Whys, it can feel natural and almost beneficial to go down all potential paths and be really comprehensive. However, this can widen the scope of how much learning and corrective actions need to occur. This is meant to be a ‘lean’ process in which picking one path allows us to perform just the amount of corrective actions needed to solve a problem.

We often have to tell ourselves we just need to pick one and go with it. If the same problem seems to occur again, then we can do another choosing the other route.

Together, we work through each of those five whys and discover actionable steps that have been or will be taken.

Step 4: Assign responsibility for solutions

At the end of the exercise, we go through each why question-and-answer pairing and come up with five related “corrective actions” that we all agree on. The master assigns responsibility for the solutions to various participants in the discussion.

Step 5: Email the whole team the results

After each 5 Whys process, someone involved in the meeting will write down what was discussed in the clearest, plainest language as possible. Then we add it to a Paper folder and—in one of the most important steps of the whole process—email the whole team with the results.

This makes sense to do, and not just for a company like Buffer that focuses on transparency. It’s super useful for everyone on your team to stay in the loop and understand any steps you’re taking as the result of a 5 Whys.

Eric Ries explains why the email is so important:

The advantage of sharing this information widely is that it gives everyone insight into the kinds of problems the team is facing, but also insight into how those problems are being tackled. And if the analysis is airtight, it makes it pretty easy for everyone to understand why the team is taking some time out to invest in problem prevention instead of new features. If, on the other hand, it ignites a firestorm – that’s good news too. Now you know you have a problem: either the analysis is not airtight, and you need to do it over again, or your company doesn’t understand why what you’re doing is important. Figure out which of these situations you’re in, and fix it.

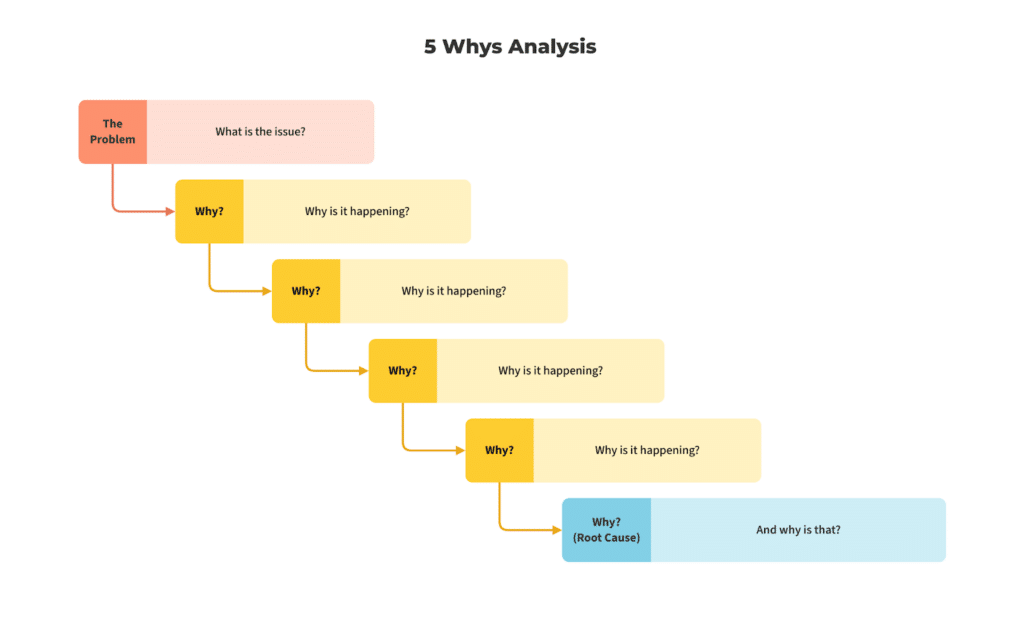

Put it all together and the process looks like this:

Some real-life 5 Whys examples

To take the 5 Whys from theoretical to actual, here’s a look at a few moments in Buffer’s history that have called for a 5 Whys meeting.

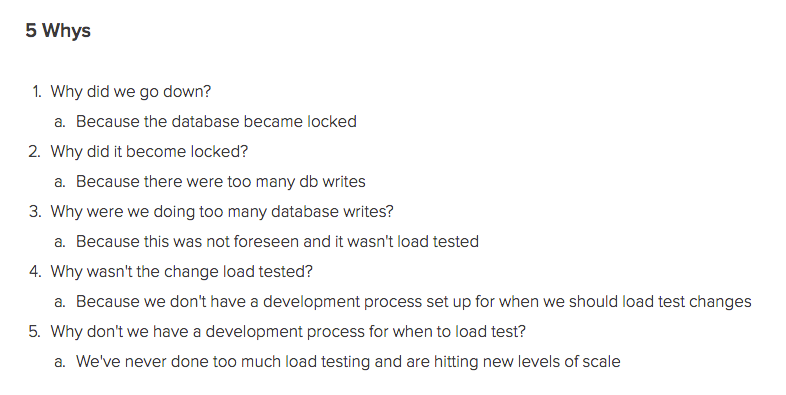

In early 2014, we had a brief systemwide outage. Here’s a look at the 5 Whys the team conducted:

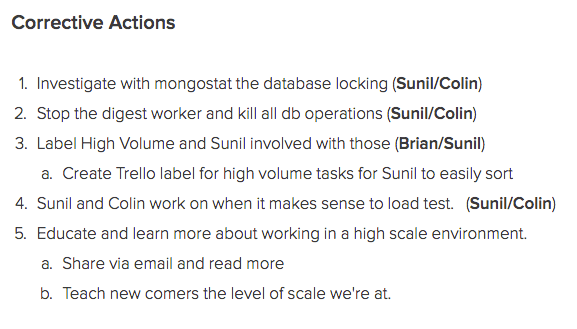

And the corrective actions that resulted:

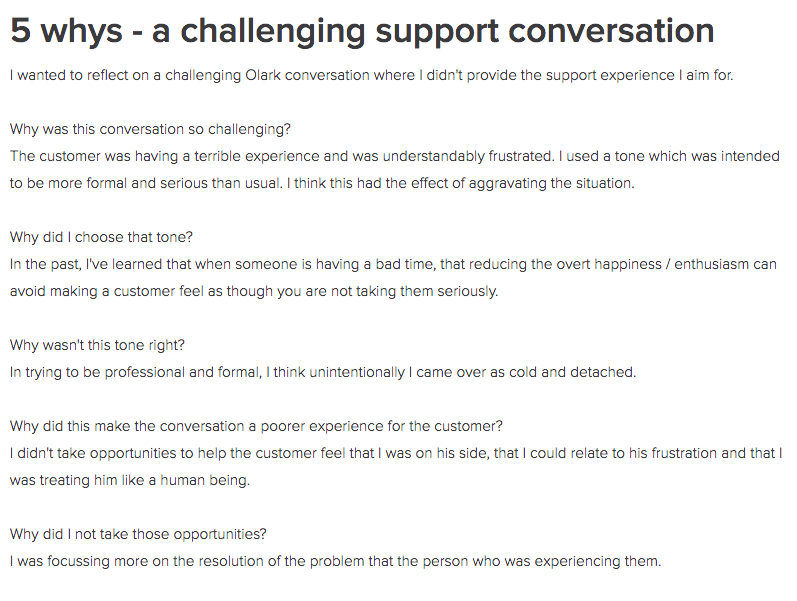

Here’s an example from the customer happiness world. One of our Happiness Heroes wanted to understand how he might have handled a customer’s problem better, so he performed a modified 5 Whys as a reflection and shared it with the team.

I have learned so much from viewing these examples and being part of 5 Whys processes. It’s been great to develop a habit of reflecting anytime something unexpected happens and taking incremental steps so that we change what happens the next time around.

The 5 Whys in daily life

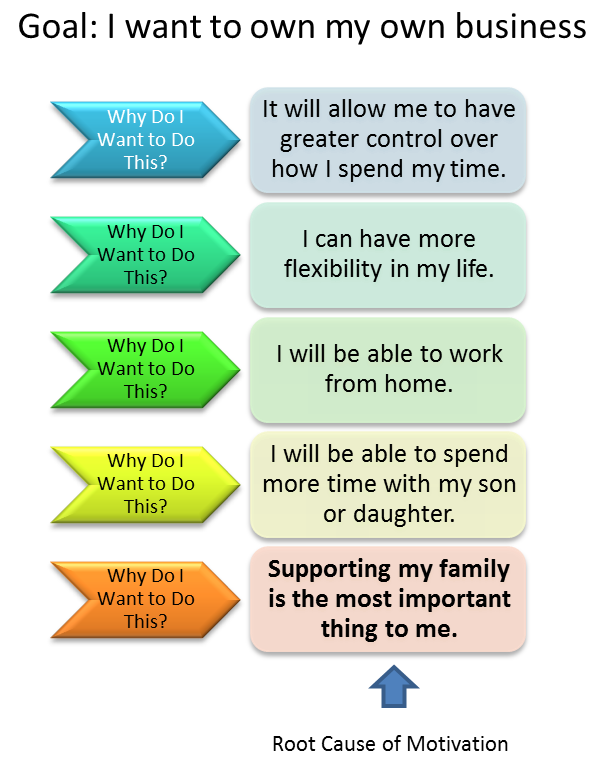

Although the 5 Whys is most widely used for manufacturing/development use, I’ve found that it is also quite applicable to daily life in any situation where one might seek deeper understanding—of a problem, a challenge or even a motivation behind an action.

This quick graphic from Start of Happiness provides a great example:

Ever since learning about the 5 Whys, I find myself asking “why?” a lot more often.

Over to you

What sort of process do you use to get to the root of unexpected situations or challenges in your work or life? Have you ever tried the 5 Whys?

I’d love to hear your insights in the comments!

P.S. If you liked this post, you might enjoy our Open blog newsletter . Receive each new post delivered right to your inbox! Sign up here .

Try Buffer for free

140,000+ small businesses like yours use Buffer to build their brand on social media every month

Related Articles

TikTok's parent company must divest the app or face a ban in the U.S. Here's everything we know, plus how to plan ahead.

How the Buffer Customer Advocacy Team set up their book club, plus their key takeaways from their first read: Unreasonable Hospitality by Will Guidara.

In this article, the Buffer Content team shares exactly how and where we use AI in our work.

140,000+ people like you use Buffer to build their brand on social media every month

Copyright © 2024 Buffer | Privacy | Terms | Security

- Social Media Marketing

- Instagram Marketing

- Social Analytics

- News and Trends

- Best apps and tools

- Inside Buffer

- Remote Work

- Transparency

- Blog & podcasts

- Best Time to Post on Social Media

- Social Media Blog

- Social Media Glossary

- About Buffer

- Our culture

- RCA 101 – 5-Why Analysis (Free Training)

- RCA 201 – Basic Failure Analysis

- RCA 301 – PROACT® RCA Certification

- RCA 401 – RCA Train The Trainer

- Other Trainings

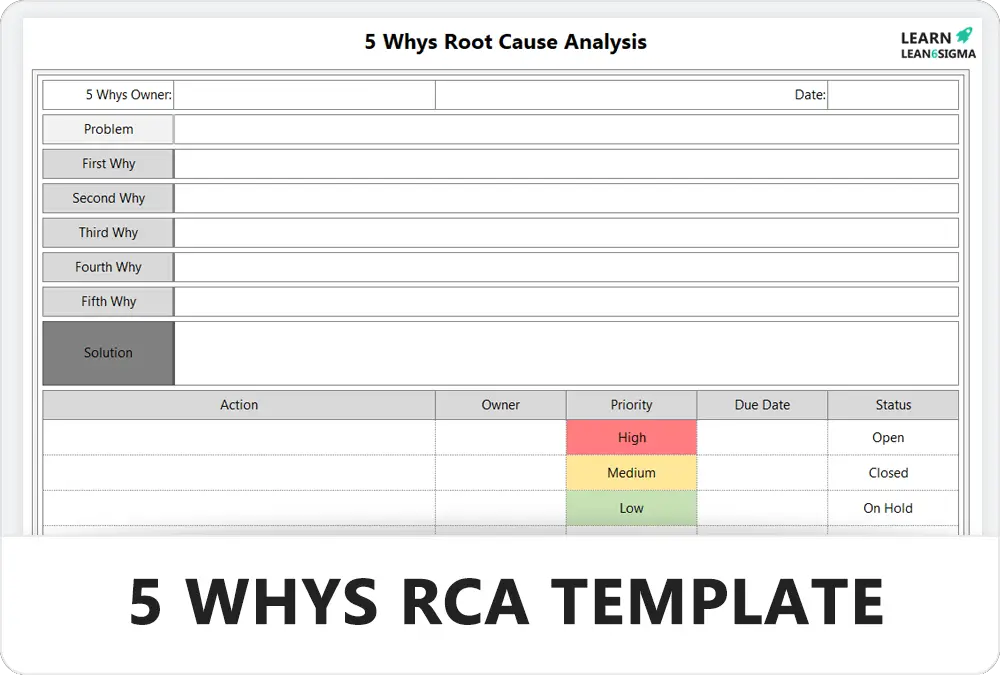

- 5 Whys Root Cause Analysis Template

- RCA Template

- Chronic Failure Calculator

Root Cause Analysis with 5 Whys Technique (With Examples)

By Sebastian Traeger

Updated: April 23, 2024

Reading Time: 7 minutes

What Is the 5 Whys Technique?

Example of the 5 whys technique, how to conduct a 5 whys analysis in 5 steps, when to use a 5 whys analysis, using 5 whys template, tips for mastering the 5 whys technique, frequently asked questions about 5 whys.

With over two decades in business – spanning strategy consulting, tech startups and executive leadership – I am committed to helping your organization thrive.

At Reliability, we’re on a mission to help enhance strategic decision-making and operational excellence through the power of Root Cause Analysis, and I hope this article will be helpful!

Our goal is to help you better understand 5 whys techniques by offering insights and practical tips based on years of experience. Whether you’re new to doing RCAs or a seasoned pro, we trust this will be useful in your journey towards working hard and working smart.

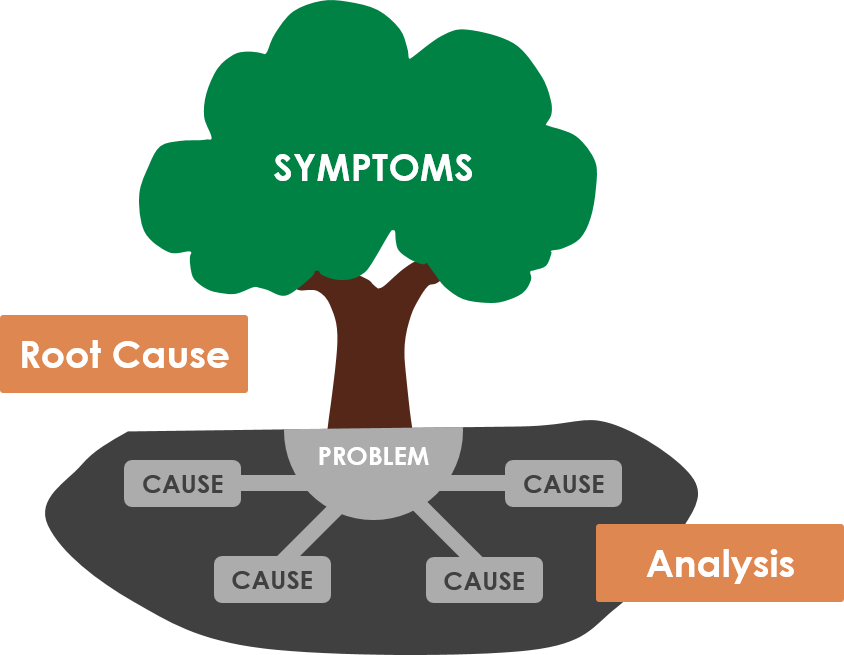

The 5 Whys Technique is like peeling an onion – it helps you uncover the underlying reasons behind a problem, layer by layer. By repeatedly asking “why” at least five times, this method digs deep to reveal the root cause of an issue. It’s a simple yet powerful problem-solving approach that aims to get to the heart of the matter rather than just addressing surface-level symptoms.

5 Whys Technique: A method that involves iteratively asking “why” five times to unveil the fundamental cause of a problem.

In essence, the 5 Whys Technique is not just about fixing what’s broken on the surface; it’s about understanding and addressing the deeper issues that lead to problems in the first place.

The 5 Whys Technique is like a detective, uncovering the truth behind recurring problems. Let’s take a look at how this method works in two different scenarios.

Case Study: Manufacturing Defects

Imagine a company that keeps encountering the same manufacturing defects despite various attempts to fix them. By using the 5 Whys Technique, they discovered that the defects were not caused by faulty machinery, as previously assumed, but rather by human error due to unclear operating instructions. This realization led to improved training procedures and clear work guidelines, ultimately eliminating the defects.

Application in Service Industry

Now, consider a service industry struggling with frequent customer complaints and service failures. Through the 5 Whys Technique, it was revealed that these issues stemmed from inadequate staffing levels during peak hours. By addressing this root cause, such as hiring additional staff or adjusting schedules, the service quality can significantly improve, leading to higher customer satisfaction.

These examples illustrate how the 5 Whys Technique can be applied across different sectors to identify and address underlying issues effectively.

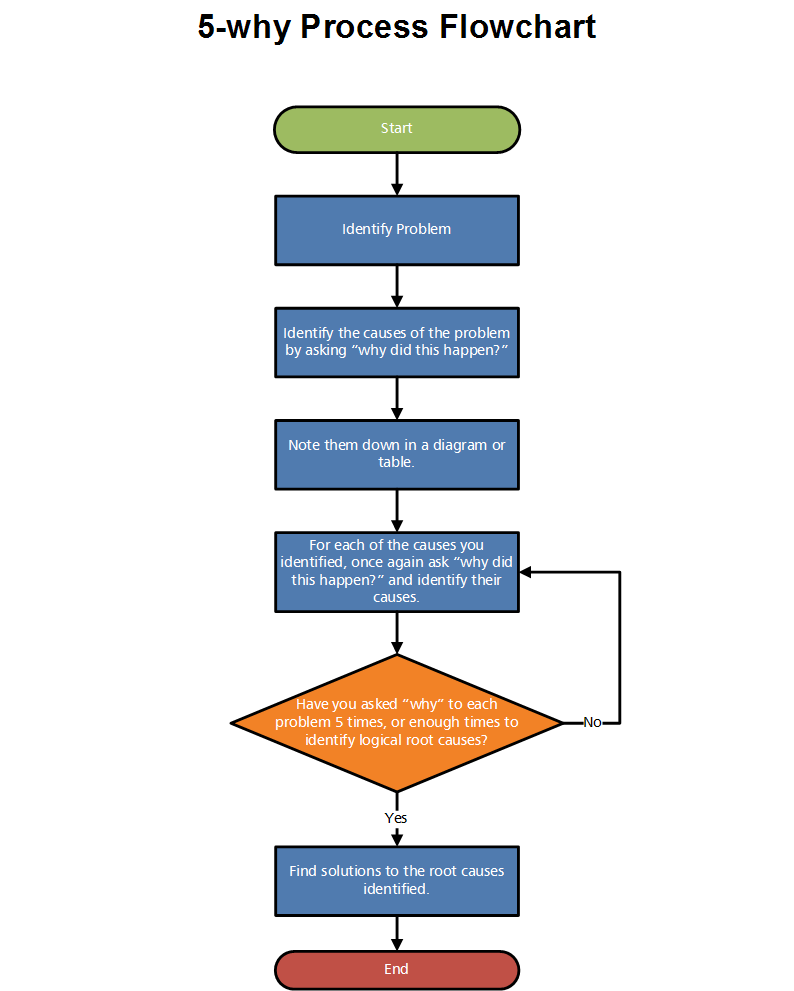

Step 1: Identify the Problem

Before diving into a 5 Whys analysis, it’s crucial to clearly identify the problem or issue at hand . This step sets the stage for the entire process and ensures that the focus remains on addressing the right concern. Take the time to gather relevant data, observe patterns, and consult with team members or stakeholders to gain a comprehensive understanding of the problem.

Step 2: Ask ‘Why’ Five Times

Once the problem is clearly defined, it’s time to start peeling back the layers. The process involves asking “why” five times, not necessarily limited to five questions but enough to delve deeper into the underlying causes of the problem . Each “why” serves as a gateway to uncovering additional factors contributing to the issue. This iterative approach helps in identifying not just one cause, but multiple interconnected elements that may be at play.

By consistently probing deeper with each “why,” you can reveal hidden complexities and nuances that may have been overlooked initially. This method allows for a more thorough understanding of the situation, paving the way for effective solutions that address root causes rather than surface-level symptoms.

This structured approach encourages critical thinking and enables teams to move beyond quick fixes towards sustainable improvements.

The 5 Whys Technique is a versatile problem-solving approach that can be applied in various scenarios to uncover root causes and drive continuous improvement. Here are two key situations where the 5 Whys Analysis can be particularly beneficial:

Recurring Issues

- The 5 Whys Technique is especially useful when dealing with recurring issues. Whether it’s a manufacturing defect that keeps resurfacing or a persistent customer complaint in the service industry, this method helps identify the underlying reasons behind these repetitive problems. By repeatedly asking “why,” it becomes possible to trace the issue back to its root cause, allowing for targeted solutions that prevent reoccurrence.

Process Improvement

- Organizations constantly strive to enhance their processes and workflows for increased efficiency and quality. When seeking to improve existing procedures, the 5 Whys Technique serves as a valuable tool. By systematically analyzing the factors contributing to inefficiencies or bottlenecks, teams can gain insights into how processes can be optimized at their core. This method enables organizations to make informed decisions about process improvements based on a deep understanding of the underlying issues.

In both cases, the 5 Whys Analysis offers a structured yet flexible approach to delve into complex problems, making it an indispensable tool for driving meaningful change and progress within organizations.

When it comes to conducting a 5 Whys analysis, utilizing a structured template can greatly facilitate the process and ensure a comprehensive investigation into the root cause identification. Using RCA software such as EasyRCA can benefit the team by streamlining your 5-why process. Here’s how organizations can benefit from using a template:

Benefits of Using a Template

- Streamlined Process: A well-designed 5 Whys template provides a clear framework for conducting the analysis, guiding teams through the iterative questioning process. This streamlines the investigation, making it easier to navigate and ensuring that no crucial aspects are overlooked.

- Thorough Investigation: By following a predefined template, teams are prompted to explore various facets of the problem systematically. This ensures that all relevant factors are considered, leading to a more thorough and insightful investigation into the underlying causes.

- Consistent Approach: Templates offer a standardized approach to conducting 5 Whys analyses within an organization. This consistency promotes uniformity in problem-solving methods across different teams or departments, enhancing overall efficiency and effectiveness.

Customizing the Template

Organizations have the flexibility to customize 5 Whys templates according to their specific needs and industry requirements. This adaptability allows for tailoring the template to address unique challenges and incorporate industry-specific considerations. Customization may include:

- Adding Industry-Specific Prompts: Tailoring the template by incorporating prompts or questions relevant to particular industries or types of issues being analyzed.

- Incorporating Visual Aids: Enhancing the template with visual aids such as flow charts or diagrams can help teams better understand and communicate complex causal relationships.

- Iterative Refinement: Regularly reviewing and refining the template based on feedback and evolving organizational needs ensures that it remains aligned with current processes and challenges.

Customizing the template empowers organizations to harness the full potential of the 5 Whys Technique in addressing diverse problems while aligning with their unique operational contexts.

Encouraging Open Communication

In mastering the 5 Whys Technique as a problem-solving method, creating an environment that fosters open communication is paramount. When team members feel comfortable expressing their perspectives and insights, it leads to a more comprehensive exploration of the underlying causes of a problem. Encouraging open communication allows for diverse viewpoints to be considered, providing a holistic understanding of the issue at hand.

By promoting an atmosphere where individuals are empowered to voice their observations and concerns, the 5 Whys analysis can benefit from a rich tapestry of ideas and experiences. This inclusive approach not only enhances the depth of the analysis but also cultivates a sense of ownership and collective responsibility for addressing root causes within the team or organization.

Continuous Improvement Mindset

A key aspect of mastering the 5 Whys Technique is embracing a continuous improvement mindset. Rather than viewing problems as isolated incidents, this approach encourages teams to see them as opportunities for growth and development. By instilling a culture of continuous improvement, organizations can leverage the insights gained from 5 Whys analyzes to drive positive change across various aspects of their operations.

Fostering a mindset focused on continuous improvement entails actively seeking feedback, evaluating processes, and implementing iterative enhancements based on the findings. It involves an ongoing commitment to learning from past experiences and leveraging that knowledge to proactively address potential issues before they escalate. Embracing this mindset ensures that the 5 Whys Technique becomes ingrained in the organizational ethos, leading to sustained progress and resilience in problem-solving efforts.

As we wrap up our exploration of the 5 Whys Technique, let’s address some common questions that may arise regarding this powerful problem-solving method.

What is the primary goal of the 5 Whys Technique?

The primary goal of the 5 Whys Technique is to uncover the root cause of a problem by iteratively asking “why” at least five times. This approach aims to move beyond surface-level symptoms and address the underlying issues that lead to recurring problems.

Is the 5 Whys Technique limited to specific industries or sectors?

No, the 5 Whys Technique is versatile and can be applied across various industries and sectors. Whether it’s manufacturing, healthcare, service, or technology, this method offers a structured yet flexible approach to identifying root causes and driving continuous improvement.

How does the 5 Whys Technique contribute to continuous improvement?

By delving into the fundamental reasons behind problems, the 5 Whys Technique provides organizations with valuable insights for driving continuous improvement. It not only helps in resolving immediate issues but also fosters a culture of ongoing enhancement and development within an organization.

Can the 5 Whys Technique be used for complex problems with multiple contributing factors?

Yes, while initially designed as a simple and straightforward method, the 5 Whys Technique can certainly be applied to complex problems with multiple interconnected factors. By systematically probing deeper into each layer of causality, this technique enables a comprehensive understanding of intricate issues.

I hope you found this guide to 5 whys technique insightful and actionable! Stay tuned for more thought-provoking articles as we continue to share our knowledge. Success is rooted in a thorough understanding and consistent application, and we hope this article was a step in unlocking the full potential of Root Cause Analysis for your organization.

Reliability runs initiatives such as an online learning center focused on the proprietary PROACT® RCA methodology and EasyRCA.com software. For additional resources, visit Reliability Resources .

- Root Cause Analysis /

Recent Posts

Ultimate Guide to Swiss Cheese Model and Its Applications

5 Root Cause Analysis Examples That Shed Light on Complex Issues

What Is Fault Tree Analysis (FTA)? Definition & Examples

Root Cause Analysis Software

Our RCA software mobilizes your team to complete standardized RCA’s while giving you the enterprise-wide data you need to increase asset performance and keep your team safe.

Root Cause Analysis Training

[email protected]

Tel: 1 (800) 457-0645

Share article with friends:

Guide: 5 Whys

Author: Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

5 Whys is a problem-solving technique used to get to the root cause of problems by asking the question of Why multiple times, but often 5 times giving it the name “5 Whys”. This allows people to address the root cause of issues instead of the symptoms of the root causes which is often what is seen as the problem.

Like a doctor diagnosing an issue such as neck pain, a painkiller will only address the symptoms of the neck pain and not the root cause of the pain. By getting to the root cause you can ensure a long-term fix to the root cause of the neck pain which could be caused by seating positions and not taking painkillers which is a short-term fix.

What is the 5 Whys?

The 5 Whys is a root cause analysis problem-solving technique that aims to identify the root cause of a problem by repeatedly asking the question “Why?” five times or until the core issue is unveiled. Developed within the Toyota Production System , it’s one of fundamental tools in the Lean Six Sigma methodology.

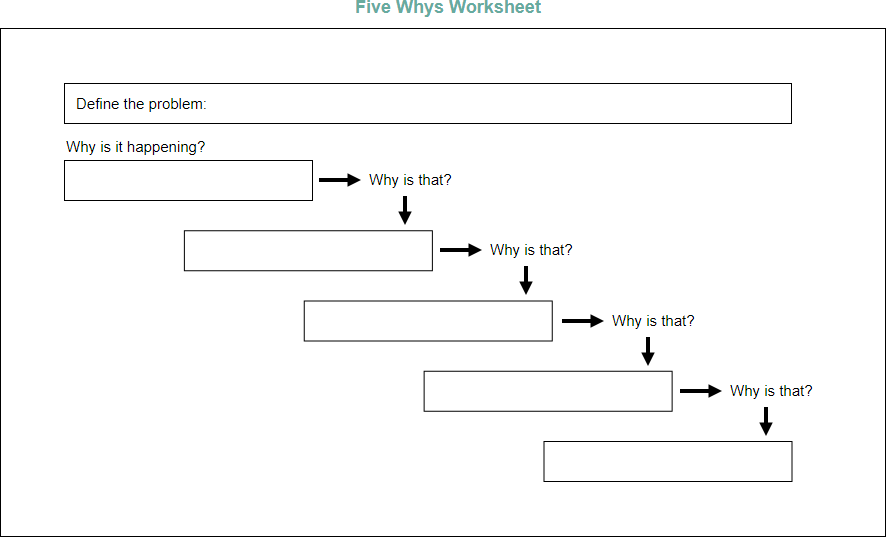

Here’s how it works:

- Begin with a clear and concise problem statement.

- Ask “Why?” the problem occurred. Document the answer.

- If this answer doesn’t identify the root cause, ask “Why?” again and document the subsequent answer.

- Continue this process until you’ve either asked “Why?” five times or the root cause has been identified.

Lets go through an example, let’s say a machine stopped working:

- Why? – The machine’s fuse blew.

- Why? – The machine was overloaded.

- Why? – There wasn’t adequate training on machine capacity.

- Why? – Training materials were outdated.

- Why? – There’s no review process for updating training materials.

In this case, the root cause is the lack of a review process for training materials, and addressing this will prevent similar issues in the future. Only treating the symptom in this situation would have been to change the fuse, for it then to regularly blow and cause additional downtime.

This is a good example where a machine stopping working’s root cause is cause by an issue what would not be obvious is first glace at the symptom of the problem and provides a clear example that root cause analysis is important to ensure that solutions are not jumped to before a through root cause analysis is conducted.

Why is the 5 Whys Important?

Understanding the 5 Whys is important because identifying symptoms of a problem is not the same as uncovering its root cause. If you only address symptoms this provides only temporary solution to the problem. However, understanding and resolving the root cause can prevent the issue from reoccurring.

The 5 Whys Problem-Solving technique is also useful for:

- Problem Prevention: By identifying the root cause of the problem, businesses can implement long-term solutions, leading to more robust systems and processes and prevent the problem reoccurring.

- Cost-Efficiency: Addressing root causes is often more cost-effective in the long run as it prevents recurrence and the associated costs of repeated problem-solving which usually involves the same people constantly firefighting the same issues such as repeated machine breakdowns.

- Improved Processes: Regular use of the 5 Whys to identify the root causes of problems can highlight weaknesses in processes, leading to continuous improvement and optimization processes.

- Empowerment: The use of 5 Whys by individuals a positive culture that promotes a deeper understanding of systems and processes, empowering teams to take ownership and responsibility in addressing issues.

How to Conduct a 5 Whys Root Cause Analysis?

Step 1: define the problem.

This is an important step as if the problem is not defined effectively it could result in focusing in the wrong problem. A good method for this could be to use the 5W1H Is/Is Not Problem solving technique to gain a common understanding of that the problem is.

When stating the problem you are going to conduct a 5 Whys on it is important to be specific about the issue and avoid ambiguous descriptions. Additionally, where data and information is available this should be collected and used as evidence that points to the actual problem rather than opinions of the problem.

Step 2: Ask the First “Why?”

Now you have a clear problem definition you should ask the question “Why did that happen?” This should be done to understand the problem without making assumptions and should be done with supporting facts and data that backs up the initial answer to the question.

Step 3: Continue to Ask Why?

Now you should have an answer to the first why. This should form the next step and ask why did that happen. This ensures you dont settle for the inisital surface-level answer or symptoms of the real problem and pushes you to understand the underlying issues.

When you continue to ask why you should:

- Continuously question the previous answer

- Challenge answer that seem like assumptions and lack evidence to support them to avoid going down the wrong route.

Step 4: Continue the Process

- Keep the questioning focused on the problem

- If you feel the questioning is going off track revert back to what the initial problem definition.

- Ensure each answer provided logically leads to the next “Why?”

- The 5 Whys process then concludes when further questions leads to no further valuable answers are given or the when the root cause of the issues becomes clear.

Step 5 Implement Solutions

Once you have identified the root cause the you need to address it by implementing a solution to prevent the problem reoccuring.

This should be a case of developing an actionable solution that address the root cause of the issue and not preventing the symptoms as addressing the symptom will likely cause the issue to reappear elsewhere.

Make sure you test the solutions to ensure they are effective in addressing the root cause, you should then continue to monitor the process over time to confirm the problem did not reappear in the same place or elsewhere.

If the problem does not re appear congratulations you have solved the problem!

An Example of 5 Whys Analysis

Below is a good example of a 5 Whys analysis done in a situation where there was a production downtime.

To summarize, the 5 Whys process is an effective problem-solving tool that can assist businesses in identifying the root cause of a problem and developing effective solutions. Teams can delve deep into underlying issues and develop targeted solutions that address the root cause of the problem by asking “why” multiple times.

The five steps of the 5 Whys process – defining the problem, asking “why” once, asking “why” more times, developing a solution, implementing the solution, provide a clear framework for problem-solving and can help ensure that the problem is effectively resolved. The 5 Whys process encourages teams to think critically and systematically, resulting in long-term solutions that are effective, targeted, and sustainable.

- Benjamin, S.J., Marathamuthu, M.S. and Murugaiah, U., 2015. The use of 5-WHYs technique to eliminate OEE’s speed loss in a manufacturing firm. Journal of Quality in Maintenance Engineering , 21 (4), pp.419-435.

A: The 5 Whys technique is a problem-solving method that involves asking “why” multiple times to uncover the root cause of a problem or issue.

A: The 5 Whys technique involves repeatedly asking “why” to identify the underlying cause of a problem. After asking “why” five times or until the root cause is revealed, you can develop effective solutions to address the issue.

A: The primary purpose of the 5 Whys technique is to identify and address the root cause of a problem. It helps organizations and individuals go beyond surface-level symptoms and understand the deeper issues affecting their processes or systems.

A: The 5 Whys technique is best used when you encounter a problem or issue that needs to be resolved. It is particularly useful for complex problems, recurring issues, or situations where multiple factors contribute to the problem.

A: Yes, the 5 Whys technique can be applied to any industry or field. It is commonly used in manufacturing, engineering, healthcare, software development, project management, and various other sectors.

A: While the technique is called the “5 Whys,” the number of “whys” you need to ask may vary. The goal is to keep asking “why” until you reach the root cause of the problem, which may require more or fewer than five iterations.

A: Yes, there are a few limitations to consider when using the 5 Whys technique. It relies on the skill and knowledge of the people involved, and it may oversimplify complex problems. Additionally, it assumes a linear cause-and-effect relationship, which may not always be accurate.

A: Yes, the 5 Whys technique can be used in a group setting. In fact, involving multiple perspectives can enhance the effectiveness of the technique and lead to more comprehensive problem-solving.

Daniel Croft

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website www.learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Download Template

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Was this helpful?

Is MasterClass right for me?

Take this quiz to find out.

Get 50% off this Father's Day.

Offer Ends Soon

How to Use the 5 Whys Technique for a Root Cause Analysis

Written by MasterClass

Last updated: Jun 7, 2021 • 4 min read

Root cause analysis (RCA) is a common process for discovering the origin of a business problem. While there are many RCA problem-solving techniques, one popular and easy technique is the 5 Whys method. Performing a 5 Whys analysis is one of the most efficient ways to both discover the root cause of a problem and ensure that steps are taken to prevent it from happening again.

- Sign up for free

- SafetyCulture

The 5 Whys: A Powerful Problem-Solving Tool

The 5 Whys can be used for everything from fixing a broken appliance to solving a complex business issue. This article discusses how you actually use it.

What is the 5 Whys Technique?

The 5 Whys is a problem-solving technique used to explore the cause-and-effect relationship that leads to a particular problem. The name derives from the method’s frequent utilization of the question “Why?” This repeating question is used to determine the root cause of a problem by repeating why the problem occurs five times. Each answer forms the basis for the next question.

It’s a simple but powerful technique that can help you get to the bottom of things in a thorough manner. It can be used for anything from figuring out why your car keeps breaking down to understanding why a project is behind schedule. It’s a great way to get clarity and find solutions fast.

When it comes to problem-solving, the 5 Whys is one of the simplest techniques around. But don’t let its simplicity fool you—it’s a powerful tool that can help you get to the root of any issue. The beauty of the 5 Whys is that it helps you get to the heart of the issue quickly and easily. And it’s a great tool for troubleshooting problems in your business. Here are some of its benefits:

- Identifies the root cause of the problem

- Helps you analyze and understand how one action can cause a chain of problems

- Gets you to the root cause quickly

- Does not use any complicated techniques for problem-solving

- Figures out the relationship between the various root causes

- Is very effective as a solution for simple problems

The 5 Whys technique was developed in the 1930s by Sakichi Toyoda, a mechanic who was always looking for ways to improve the efficiency of his work. He found that the best way to do this was to ask why his processes were failing. He would ask why five times until he got to the root of the problem. Simple as that!

The 5 whys is now a popular problem-solving technique that’s used in businesses all over the world. It’s simple yet amazingly effective at getting to the root of a problem.

How It Works

Let’s say you’ve got a problem. You know what it is, but you’re not sure how to fix it. This is where the 5 Whys come in.

Here’s how it works: you ask yourself why the problem happened, and then you ask yourself that question again and again until you get to the root of the issue.

The key is to ask why five times. Why did the problem happen? Why did the previous solution fail? And so on. This helps you get down to the root cause of the issue and find a solution that will actually work.

This is a great technique when you’re stuck and don’t know how to move forward. It can help you get clarity and come up with a solution that works for you.

Here’s a perfect example:

| The customer refused to pay for the product. | |

| Why? | The customer saw that there was damage to the product when it was opened. |

| Why? | The product got damaged during the delivery. |

| Why? | The product, which is made of glass, fell causing it to crack. |

| Why? | There was no safety packaging for the product. |

| Why? (Root Cause) | It was not properly inspected during the packaging process. |

Digitize the way you Work

Empower your team with SafetyCulture to perform checks, train staff, report issues, and automate tasks with our digital platform.

What are the 5 Whys in Six Sigma?

The 5 whys tools can be used in a variety of situations. It’s used in root cause analysis and Six Sigma to get to the root of a problem.

As we all know, Six Sigma is a process improvement methodology used in various industries to achieve near-perfection in their processes. Within that metholodogy, the 5 whys tool is used specifically for the DMAIC (Define, Measure, Analyze, Improve, and Control) framework.

As a result, it helps Six Sigma practitioners find the root cause of a problem by asking successive “why” questions.

When to Use this Method

This technique can be used when you’re trying to solve a specific problem understand why something went wrong. It can also be used to come up with new ideas or solutions.

The great thing about the 5 Whys is that it helps you get to the root of the problem, and it also encourages creativity and brainstorming. So if you’re facing a challenging problem, this is a technique you should try.

Limitations

The 5 Whys is a great tool for problem-solving, but it has some limitations. For example, it can be difficult to apply this technique to more complex problems. Aside from this, here are some of the constraints when using this method:

- This method is not recommended for complex problems as it may not lead to the main cause. This is because the 5 whys will lead to a single source, which may be a problem if there is a need for multiple solutions.

- It is reliant on the skills of the team facilitator. One wrong question or answer can lead to completely throwing off the questions, thus leading to a wrong root cause.

- The 5 whys method may not show all possible issues caused by the main problem.

How to Use the 5 Whys Method

Now that you know all about the 5 Whys method, let’s talk about how to use it. So how do you implement the 5 Whys tool? Here’s a quick and easy guide to get you started:

#1. Gather and Assemble a Team.

The first step is to create a team that is familiar with the problem or issue at hand. Familiarity with the issue is essential because this will determine the right questions to ask thus solving the problem correctly.

#2. Identify the Problem.

Next is to identify the problem at hand. Once you’ve done that, it’s time to discuss it with your team by writing down a brief statement or question of what the agreed issue needs to be solved. A team member can right down the statement while leaving enough space for why questions.

#3. Ask the 5 Whys.

Now is the time to ask the first why. The first question must pertain to why the problem occurred. The question must be based on facts and related to the issue. Keep going until you reach the root cause of the problem.

#4. Brainstorm Solutions to the Root Cause.

Once you’ve identified the root cause, you can start brainstorming solutions. It’s important to remember that not every solution will work, but the goal is to find a solution that will prevent the problem from happening again.

#5. Test the Solution.

So how do you know if the solution is effective? You need to test it. Modify the solution as needed and repeat the test until you’re satisfied that it’s working.

How Can SafetyCulture Help with Using 5 Whys?

The 5 Whys is a great tool for solving problems quickly and easily, and it can be used in situations wherein you need to find the cause of the problem. But how SafetyCulture (formerly iAuditor) can help you with using 5 Whys?

SafetyCulture is a powerful analytical tool and 5 whys software that can help you quickly and easily identify the root cause of any problem. Plus, the platform’s reporting and dashboard capabilities make it easy to share your findings with your team. Here are some other features that you can utilize when doing 5 whys analysis with SafetyCulture:

- Capture and report issues to gain better visibility and traceability, and get to the root cause using relevant insights and data for continuous improvement .

- Use the Heads Up feature to keep everyone in the loop during 5 Whys meetings. With this feature, you’ll never miss team meetings, ensure all agenda are addressed, and easily collect the additional necessary data to streamline the process.

- Assign actions to team members that are in charge of making sure that the 5 whys analysis progresses and that tasks are properly assigned through building workflows .

- Use various smart checklists and templates that you can customize based on your team’s needs.

- Integrate your tools to assess all kinds of data and monitor analytics in one place.

Featured Templates:

The 5 Whys Template

Can I use 5 Whys in any situation or problem that occur?

Yes and no. The great thing about 5 whys is that it can be used by anyone facing simple problems. However, for complex problems that require detailed solutions, using 5 whys may not be ideal.

Why are there only five "whys"?

The 5 Whys technique is based on the premise that the root cause of a problem can be found by asking why five times. With this method, you can get to the root of the issue and find appropriate solutions.

How do I know when I've reached the root cause?

There is no hard and fast rule for how many times you should ask why before you reach the root cause. However, if you find yourself going in circles or asking the same question multiple times, it’s likely that you haven’t yet reached the root cause.

How do you document 5 Whys?

There are various ways to document 5 whys. One way is to use a cause and effect diagram, also known as an Ishikawa diagram or fishbone diagram. This type of diagram can be used to brainstorm the possible causes of a problem. Another way to document 5 whys is to simply write down the question and answer for each step.

SafetyCulture Content Team

Related articles.

- Change Management Models

Explore the different change management models and choose the best one for your business by learning their pros, cons, and use cases.

- Find out more

- Procurement Strategy

Discover the benefits of procurement strategy, its importance in business operations, and how to properly implement it to achieve organizational success.

- Distribution Management

Learn what distribution management is, how it affects operations, and the key components of an effective distribution management system.

Related pages

- Process Control Software

- Change Management Software

- Critical Event Management Software

- Open Innovation Platform

- Business Process Improvement Software

- Digital Transformation Training

- Change Impact Assessment

- Change Impact Assessment Template

- Environmental Aspects and Impacts Register

- 5 Whys Template

- Agile Transformation Checklist

- CSR Audit Checklist

5 Whys: Examples, explanations, and how to find the causes of problems

At some point, we’ve all experienced a problem with a process or strategy at work. But figuring out why the problem exists can be a daunting task. When you sit your teammates down for a discussion, emotions run high and miscommunication is common.

The 5 Whys is a powerful, easy-to-use technique for getting at the root of a problem. It empowers you and your team to understand why a problem persists and to decide on a path forward.

- What is the 5 Whys framework?

The 5 Whys is a popular problem-solving method that individuals and teams use to understand the potential causes of a specific issue. Years ago, Toyota developed the approach to help them get at the heart of complex mechanical issues, so you know it’s legitimate! The technique is easy to use: you ask why a problem happened, and then you ask four more times. By asking “why” on a step-by-step basis, you can get to the root cause of a defect, failure, challenge, or malfunction.

- When and Why the 5 Whys Analysis is Used

The 5 Whys framework is useful in a variety of situations. People love it because it helps you have a focused discussion and avoid getting distracted by other topics. You just start with a problem statement, ask why the problem exists, and keep moving through the exercise until you’ve uncovered the problem.

Here are some scenarios where you might find the 5 Whys approach to be useful.

Working on complex products

Remember, the 5 Whys technique was originally developed by Toyota. The car manufacturer needed a clear-cut way of dealing with a product that has thousands of parts. But that doesn’t mean the technique only works for large physical goods. Many organizations use the 5 Whys approach when software malfunctions, when a key deliverable with many moving parts doesn’t work properly, or when a multi-step process breaks down.

Solving complex problems

When a problem is so complex that engineers, designers, or decision-makers are scratching their heads, the 5 Whys approach may serve you well. Maybe your complicated marketing strategy didn’t hit your targets, or an important API isn’t working. Instead of getting overwhelmed, the 5 Whys framework helps you wrap your head around the problem.

Dealing with consistent problems

Maybe the problem doesn’t seem complex, but it keeps coming up. Or maybe you’ve tried multiple solutions and none seem to work. Rather than burning precious time and money on yet another risky bandaid, try the 5 Whys to finally discover what’s going on.

- How to conduct a 5 Whys analysis in 6 steps

One of the great things about the 5 Whys framework is that it’s easy to understand. Unlike many other problem-solving techniques, which can be difficult to grasp, you can explain the 5 Whys to your team in minutes. Follow these guidelines any time you need to use the approach.

Step 1 – Form your problem statement.

Start by asking your team what problem you’re about to analyze. Everyone should get a chance to articulate the problem so you’re all on the same page. Sometimes, you might find yourself using the 5 Whys approach to uncover the root of a difficult or charged obstacle. If that’s the case, give your team the time and space to be honest with each other and to have difficult conversations. Write down the problem statement for everyone to reference.

Step 2 – Ask “why has this happened?” 5 times.

Don’t be too literal with it. Feel free to amend the “why” statement to something like “Why does this keep happening?” or “Why are we having this problem?” Keep going until you’ve asked “why” five or more times. It might feel unnatural, but eventually, you’ll push through any awkwardness to uncover the root of the problem.

Step 3 – Jot down logical causes.

Okay, now you have a pretty good handle on your problem. Write down any logical causes that have followed from your 5 Whys analysis. Regardless of whether those causes came from your first “why” or your fifth, make a detailed note of them. Discuss the causes with your team and make sure you’re all agreed.

Step 4 – Hypothesize an answer.

Now that you have your logical cause, it’s time to come up with some potential solutions. At this stage, you’re just having a conversation. You don’t need to come up with the perfect solution in this meeting. Have everyone go around the room and say (or write down) a possible solution. Ask everyone to vote on the most actionable one.

Step 5 – Test your hypothesis.

Put your solution to the test with some experiments. If you’ve decided that a marketing campaign failed because you didn’t choose the correct target audience, then maybe you can come up with some A/B tests to vet possible solutions. Aim for low-stakes tests that you can use to draw meaningful conclusions.

Step 6 – Repeat until solved.

Iterate until you’ve solved the problem! Don’t be discouraged if it doesn’t happen right away. Sometimes, it might take multiple rounds of “whys” followed by many rounds of testing to uncover a solution. Keep an open line of communication among your teammates and don’t give up.

Try Miro today

- A simple 5 Whys example

The 5 Whys is an adaptable, easy-to-use framework for uncovering the root of a problem. Organizations and teams of all sizes use the framework to overcome complex, high-stakes challenges. Here’s a quick example to help you bring this method of analysis to your own team.

Let’s say your team has been working on an app for many months. You rolled out a beta version late last quarter. You were supposed to ship the app to the rest of your users at the beginning of this quarter, but a problem arose: a bunch of your early users complained of a fatal error that caused the app to crash. As a result, you couldn’t ship it, and your customers were disappointed.

Step 1 — Write down your problem statement.

As we mentioned above, the first step in following the 5 Whys framework is to clearly and succinctly define what problem you’re trying to solve. The entire group should be clear about this issue. In this case, the problem statement is: your app wasn’t ready to ship to your customers.

Step 2 — Start with the broadest possible question.

Start with the broadest possible question. Then aim to answer it. Why wasn’t the app ready for your customers? It wasn’t ready because there was a bug in the code that caused it to crash.

Drill down into that question. Why was there a bug in the code that caused it to crash? There was a bug in the code because the engineers didn’t get user feedback in time to fix it.

Keep drilling down. Why didn’t the engineers get that user feedback? They didn’t get the feedback because the development team didn’t provide an easy way for users to submit their feedback.

Continue drilling down, asking more and more precise questions as you get closer to the answer. Why didn’t the development team provide an easy way for users to leave feedback? They didn’t provide an easy way for users to leave feedback because they weren’t clear on deadlines for the project.

Ask “why” at least one more time. Why wasn’t the development team clear on deadlines for the project? They weren’t clear on deadlines because they weren’t meeting with stakeholders often enough to know when the timeline changed.

Step 3 – Write down logical issues.

Now you have enough information to write down logical causes. It seems that this problem stemmed from a lack of communication between stakeholders. That caused the development team and engineering team to become misaligned.

Step 4 – Once you’re ready, you can come up with a possible solution to this problem.

Once you’re ready, you can come up with a possible solution to this problem. In the future, internal stakeholders will hold weekly check-ins to make sure they’re aligned on where the project is headed.

Step 5 – Put that hypothesis into action.

Here’s where you get to test out your hypothesis and see what effects it has. Moving forward, start holding weekly check-ins and see what happens. If miscommunication and confusion goes down, you’ll know you’re on the right track.Step 6 – Adjust your strategy, if needed

Resist the urge to consider a problem “solved” and move on immediately. It’s important to revisit how the solution is functioning in the weeks ahead, continually checking in with everyone on the team to see how they’re feeling about it. You may need to tweak your strategy over time.

- How 5 Whys helped solve the problem

This example clearly showcases the power of the 5 Whys. What looked like a problem with code turned out to be a symptom of miscommunication.

Although this is just a hypothetical, we all know stuff like this happens every day. But it’s often difficult to uncover the root causes of a problem without months and months of exploration. With the 5 Whys, you can overcome costly challenges in a much shorter amount of time.

- Try the 5 Whys template for free

Clearly, asking “why?” isn’t just a technique used by persistent 4-year-olds – it’s actually a quick and easy way to identify a root cause. Countless teams across different industries have had great results using this framework. Save time, collaborate with your team, and solve hard problems with Miro’s free 5 Whys template .

- How Miro helps distributed teams collaborate

Working with a remote team can be challenging — but it also offers unparalleled opportunities for creativity and collaboration. Miro’s online whiteboard helps teams overcome cultural divides, communication silos, geographic barriers, and micro-cultures to empower you to stay connected and do great things.

Miro has a variety of templates and tools for teams to help you and your team:

- Create a mind map

- Manage a scrum board

- Create user story maps and customer journey maps

- Work with sticky notes, even if you aren’t in the same room

- Generate flow charts and diagrams

- Run brainstorming sessions

And lots more… try Miro for remote collaboration today!

Miro is your team's visual platform to connect, collaborate, and create — together.

Join millions of users that collaborate from all over the planet using Miro.

Keep reading

How i do it in miro: networking diagramming with software engineer andre mocke.

How to get started with visual thinking: Diversify your brainstorm sessions with these visual thinking techniques

How I do it in Miro: Streamline your sprint planning with Rosanna Knottenbelt

- Join Mind Tools

Getting to the Root of a Problem Quickly

Have you ever had a problem that refused to go away? No matter what you did, sooner or later it would return, perhaps in another form.

Stubborn or recurrent problems are often symptoms of deeper issues. "Quick fixes" may seem convenient, but they often solve only the surface issues and waste resources that could otherwise be used to tackle the real cause.

In this article and in the video, below, we look at the 5 Whys technique (sometimes known as 5Y). This is a simple but powerful tool for cutting quickly through the outward symptoms of a problem to reveal its underlying causes, so that you can deal with it once and for all.

Click here to view a transcript of this video.

Origins of the 5 Whys Technique

Sakichi Toyoda, the Japanese industrialist, inventor, and founder of Toyota Industries, developed the 5 Whys technique in the 1930s. It became popular in the 1970s, and Toyota still uses it to solve problems today.

Toyota has a "go and see" philosophy. This means that its decision making is based on an in-depth understanding of what's actually happening on the shop floor , rather than on what someone in a boardroom thinks might be happening.

The 5 Whys technique is true to this tradition, and it is most effective when the answers come from people who have hands-on experience of the process or problem in question.

The method is remarkably simple: when a problem occurs, you drill down to its root cause by asking "Why?" five times. Then, when a counter-measure becomes apparent, you follow it through to prevent the issue from recurring.

The 5 Whys uses "counter-measures," rather than "solutions." A counter-measure is an action or set of actions that seeks to prevent the problem from arising again, while a solution may just seek to deal with the symptom. As such, counter-measures are more robust, and will more likely prevent the problem from recurring.

When to Use a 5 Whys Analysis

You can use 5 Whys for troubleshooting, quality improvement, and problem solving, but it is most effective when used to resolve simple or moderately difficult problems.

It may not be suitable if you need to tackle a complex or critical problem. This is because 5 Whys can lead you to pursue a single track, or a limited number of tracks, of inquiry when, in fact, there could be multiple causes. In cases like these, a wider-ranging method such as Cause and Effect Analysis or Failure Mode and Effects Analysis may be more effective.

This simple technique, however, can often direct you quickly to the root cause of a problem. So, whenever a system or process isn't working properly, give it a try before you embark on a more in-depth approach – and certainly before you attempt to develop a solution.

The tool's simplicity gives it great flexibility, too, and 5 Whys combines well with other methods and techniques, such as Root Cause Analysis . It is often associated with Lean Manufacturing , where it is used to identify and eliminate wasteful practices. It is also used in the analysis phase of the Six Sigma quality improvement methodology.

How to Use the 5 Whys

The model follows a very simple seven-step process:

1. Assemble a Team

Gather together people who are familiar with the specifics of the problem, and with the process that you're trying to fix. Include someone to act as a facilitator , who can keep the team focused on identifying effective counter-measures.

2. Define the Problem

If you can, observe the problem in action. Discuss it with your team and write a brief, clear problem statement that you all agree on. For example, "Team A isn't meeting its response time targets" or "Software release B resulted in too many rollback failures."

Then, write your statement on a whiteboard or sticky note, leaving enough space around it to add your answers to the repeated question, "Why?"

3. Ask the First "Why?"

Ask your team why the problem is occurring. (For example, "Why isn't Team A meeting its response time targets?")

Asking "Why?" sounds simple, but answering it requires serious thought. Search for answers that are grounded in fact: they must be accounts of things that have actually happened, not guesses at what might have happened.

This prevents 5 Whys from becoming just a process of deductive reasoning, which can generate a large number of possible causes and, sometimes, create more confusion as you chase down hypothetical problems.

Finding This Article Useful?

You can learn another 44 problem-solving skills, like this, by joining the Mind Tools Club.

Subscribe to Our Newsletter

Receive new career skills every week, plus get our latest offers and a free downloadable Personal Development Plan workbook.

Your team members may come up with one obvious reason why, or several plausible ones. Record their answers as succinct phrases, rather than as single words or lengthy statements, and write them below (or beside) your problem statement. For example, saying "volume of calls is too high" is better than a vague "overloaded."

4. Ask "Why?" Four More Times

For each of the answers that you generated in Step 3, ask four further "whys" in succession. Each time, frame the question in response to the answer you've just recorded.

Try to move quickly from one question to the next, so that you have the full picture before you jump to any conclusions.

The diagram, below, shows an example of 5 Whys in action, following a single lane of inquiry.

Figure 1: 5 Whys Example (Single Lane)

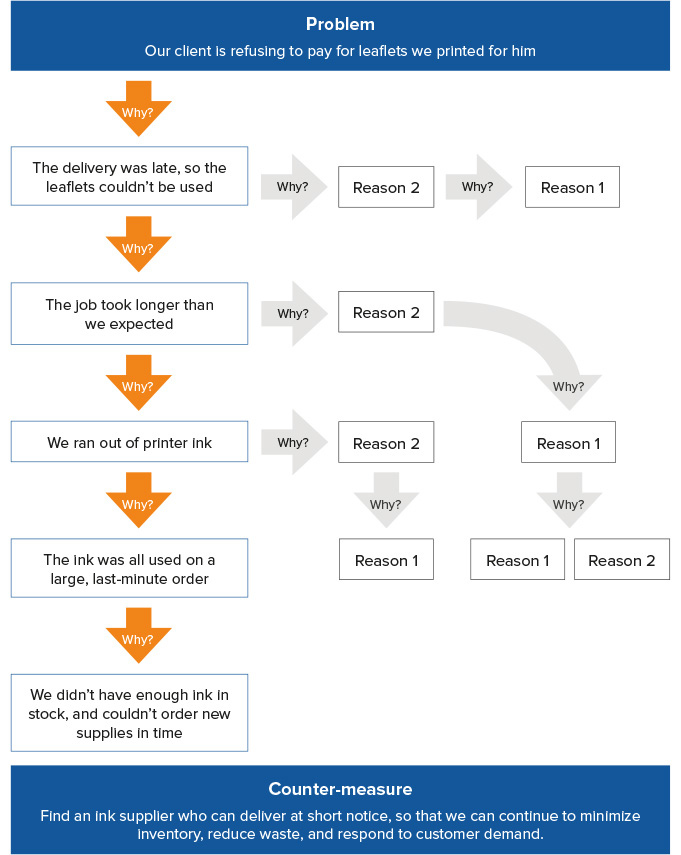

The 5 Whys method also allows you to follow multiple lanes of inquiry. An example of this is shown in Figure 2, below.

In our example, asking "Why was the delivery late?" produces a second answer (Reason 2). Asking "Why?" for that answer reveals a single reason (Reason 1), which you can address with a counter-measure.

Similarly, asking "Why did the job take longer than expected?" has a second answer (Reason 2), and asking "Why?" at this point reveals a single reason (Reason 1). Another "Why?" here identifies two possibilities (Reasons 1 and 2) before a possible counter-measure becomes evident.

There is also a second reason for "Why we ran out of printer ink" (Reason 2), and a single answer for the next "Why?" (Reason 1), which can then be addressed with a counter-measure.

Figure 2: 5 Whys Example (Multiple Lanes)

Step 5. Know When to Stop

You'll know that you've revealed the root cause of the problem when asking "why" produces no more useful responses, and you can go no further. An appropriate counter-measure or process change should then become evident. (As we said earlier, if you're not sure that you've uncovered the real root cause, consider using a more in-depth problem-solving technique like Cause and Effect Analysis , Root Cause Analysis , or FMEA .)

If you identified more than one reason in Step 3, repeat this process for each of the different branches of your analysis until you reach a root cause for each one.

The "5" in 5 Whys is really just a " rule of thumb ." In some cases, you may need to ask "Why?" a few more times before you get to the root of the problem.

In other cases, you may reach this point before you ask your fifth "Why?" If you do, make sure that you haven't stopped too soon, and that you're not simply accepting "knee-jerk" responses.

The important point is to stop asking "Why?" when you stop producing useful responses.

As you work through your chain of questions, you may find that someone has failed to take a necessary action. The great thing about 5 Whys is that it prompts you to go further than just assigning blame , and to ask why that happened. This often points to organizational issues or areas where processes need to be improved.

6. Address the Root Cause(s)

Now that you've identified at least one root cause, you need to discuss and agree on the counter-measures that will prevent the problem from recurring.

7. Monitor Your Measures

Keep a close watch on how effectively your counter-measures eliminate or minimize the initial problem. You may need to amend them, or replace them entirely. If this happens, it's a good idea to repeat the 5 Whys process to ensure that you've identified the correct root cause.

Appreciation

A similar question-based approach known as "appreciation" can help you to uncover factors in a situation that you might otherwise miss.

It was originally developed by the military to assist commanders in gaining a comprehensive understanding of any fact, problem or situation. But you can also apply it in the workplace.

Starting with a fact, you first ask the question, "So what?" – in other words, what are the implications of that fact? Why is this fact important?

You then continue asking that question until you've drawn all possible conclusions from it.

The major difference between this and the 5 Whys technique is that appreciation is often used to get the most information out of a simple fact or statement, while 5 Whys is designed to drill down to the root of a problem.

Bear in mind that appreciation can restrict you to one line of thinking. For instance, once you've answered your first "So what?" question, you might follow a single line of inquiry to its conclusion. To avoid this, repeat the appreciation process several times over to make sure that you've covered all bases.

The 5 Whys strategy is a simple, effective tool for uncovering the root of a problem. You can use it in troubleshooting, problem-solving, and quality-improvement initiatives.

Start with a problem and ask why it is occurring. Make sure that your answer is grounded in fact, and then ask the question again. Continue the process until you reach the root cause of the problem, and you can identify a counter-measure that will prevent it from recurring.

Bear in mind that this questioning process is best suited to simple or moderately difficult problems. Complex problems may benefit from a more detailed approach, although using 5 Whys will still give you useful insights.

Infographic

You can see our infographic on the 5 Whys method here:

This site teaches you the skills you need for a happy and successful career; and this is just one of many tools and resources that you'll find here at Mind Tools. Subscribe to our free newsletter , or join the Mind Tools Club and really supercharge your career!

Rate this resource

The Mind Tools Club gives you exclusive tips and tools to boost your career - plus a friendly community and support from our career coaches!

Comments (77)

- Over a month ago BillT wrote Hi hunyakvera, Thanks for your observant feedback. Sakichi Toyoda died in October of 1930, and is the creator of the 5 Whys. Also, he is stated as the founder of Toyota as he challenged his son to start a business that applied the principles of Lean and the 5 Whys. His son Kiichiro first continued with the loom company, and then decided he could do the same for any company, primarily a car company that he called Toyota. BillT Mind Tools Team

- Over a month ago hunyakvera wrote Hi! Great article. However Sakichi Toyoda died in the year 1930, so i don't see how he could have developed this technique in the 1930s. Either 1930 in his last year of life, or the date is wrong. Also, he wasn't the founder of Toyota. His son was. However, he was the founder of Toyoda companies, but not Toyota

- Over a month ago Midgie wrote Hi MGlasscock, Welcome to the Club! Indeed this 5 Whys approach is a great technique to get to the bottom of things! It would be great to meet you so come on over to the Forums and introduce yourself. Also if you have any questions, just let us know and we will be happy to help. Midgie Mind Tools Team

Please wait...

How to conduct a 5 whys analysis

Lucid Content

Reading time: about 6 min

It’s an exciting time to be alive. We have answers to conceivably any question, and they all can be accessed in a matter of seconds from a device no larger than our hand.

And yet, despite endless resources, even the best plans go awry—problems still exist that baffle even the strongest of teams. When an unexpected challenge arises, it’s difficult to locate the root of the problem.

Luckily, there’s a solid technique for locating the origin of any difficulty, and it’s called the 5 whys. The 5 whys analysis is a proven technique used by some of the world’s largest companies, and all it requires is a bit of thought (and potentially a Lucidchart template).

The beginning of the 5 whys

The five whys analysis was developed by Taiichi Ohno, the pioneer of the Toyota Production System in the 1950s. He details his method of problem solving in his book, Toyota Production System: Beyond Large-Scale Production . The technique Ohno developed was so effective that Toyota uses it to this day. Ohno saw a problem not as a negative but as an opportunity in disguise.

When approaching a problem in this manner, it becomes an investigative journey and not a barrier. It’s a way to find hope in circumstances that seem dire or overwhelming. Here’s an example of a time Ohno used the five whys to discover the reason for a robot stopping on the assembly room floor:

- "Why did the robot stop?" The circuit has overloaded, causing a fuse to blow.

- "Why is the circuit overloaded?" There was insufficient lubrication on the bearings, so they locked up.

- "Why was there insufficient lubrication on the bearings?" The oil pump on the robot does not circulate sufficient oil.

- "Why does the pump not circulate sufficient oil?" The pump intake is clogged with metal shavings.

- "Why is the intake clogged with metal shavings?" Because there is no filter on the pump.

As you can see in this example, the five whys helped Ohno reach the root cause of the issue: The team needed to add a filter to the oil pump on the robot. You can use the same process to reach the root cause and implement lasting change.

When to use the 5 whys

The five whys can be used for most problems, but it’s most effective for simple to semi-difficult problems. If you’re attempting to solve for complicated difficulties, you’ll find that the root causes split into separate tracks of inquiry that have their own root causes.

In other words, don’t try to solve the reasons for global poverty by asking five questions—it’s much too complex an issue.

Instead, whittle larger problems into smaller ones and solve the root causes of those problems. Use the five whys for manufacturing problems, product release problems, team issues, or organizational problems.

What are the 5 whys?

Every journey comprises steps—at its core, the five why analysis involves asking “Why?” five times, but we recommend adding two additional steps, covered in the next section. This process will enable you to discover the root cause of a problem.

Use Lucidchart to visualize the five whys and keep track of the root causes throughout the investigative process. Our five why diagram can be used again and again to solve whatever small- to medium-sized problems you may experience.

How to use the 5 whys

Though the core of five whys problem solving is only asking five questions, we recommend a few additional steps to bring the brainpower of your team members together and take action on the root causes you find. Use the following method for your five why approach:

1. Gather your team

It’s true that the five whys can be used to solve everyday problems, but you’ll most likely use the five whys in a business setting, so assemble together everyone who is immediately affected by the problem. We’re not talking about an all-hands meeting: Just include those who care most about the solution and can help brainstorm.

2. Define the issue

This step may be easier said than done: sometimes, it’s hard to narrow down exactly what the main problem is. Once you’ve determined the problem, write it down in a one-sentence statement that your team agrees on. Put this sentence in the white bubble at the top of the five whys Lucidchart template.

3. Ask “Why?”

This is where it gets tricky. With your team’s help, ask what’s causing the main problem. These questions need to address concrete problems, not just theories. If you use the Lucidchart template, write this first question in the left-most blue circle.

4. Ask “Why?” four more times

Following the template above in the single lane on the left, ask “why” for each answer. Here’s an example of what that could look like:

Problem: The website wasn’t launched in time.

Answer 1: The developers didn’t have the content they needed.

Answer 2: The copywriter didn’t provide the content.

Answer 3: The copywriter was waiting on approval from the VP of marketing.

Answer 4: The VP of marketing forgot to approve the content.

Answer 5: He was on a business trip.

Solution: A possible solution could be authorizing someone else to approve the content or directing the VP of marketing to set aside time for content approval.

5. Stop at a good solution

In some instances, your team may need to keep asking more “whys.” Sometimes you may need to split into more root causes. But knowing when to stop is a valuable part of the process; otherwise, you’ll find yourself lost and without fixable root causes.

6. Fix the root cause of the problem

Once you know what the root cause of the problem is, you can implement solutions to it. Discuss the best solutions with your team and decide how to proceed.

7. See how it works!

After you’ve implemented your solutions to the root causes, see how it works. Sometimes it’s perfect, and you’ve solved a major problem. Other times, you may need to tweak your “why” questions and their answers. In those instances, just rework the whys, find the root causes, and identify more solutions. The solutions should be targeted and measured and should directly impact the root causes of the whys.

The beauty of the five why process isn’t that it’s perfect: It’s that it gives you a method to rationally find solutions to baffling problems. It’s a way to find calm in a storm of issues. And, frankly, if it worked for Toyota and for a host of other massive companies, it could be the right path for your team.

Learn more about how Lucidchart can help you identify and improve your processes.

About Lucidchart

Lucidchart, a cloud-based intelligent diagramming application, is a core component of Lucid Software's Visual Collaboration Suite. This intuitive, cloud-based solution empowers teams to collaborate in real-time to build flowcharts, mockups, UML diagrams, customer journey maps, and more. Lucidchart propels teams forward to build the future faster. Lucid is proud to serve top businesses around the world, including customers such as Google, GE, and NBC Universal, and 99% of the Fortune 500. Lucid partners with industry leaders, including Google, Atlassian, and Microsoft. Since its founding, Lucid has received numerous awards for its products, business, and workplace culture. For more information, visit lucidchart.com.

Related articles

What is gap analysis 4 steps and examples to use.

A strong gap analysis process allows professionals to determine where their businesses are—and where they want it to be. To perform a gap analysis, follow these four simple steps.

7 steps of the decision-making process

Prevent hasty decision-making and make more educated decisions when you put a formal decision-making process in place for your business.

Bring your bright ideas to life.

or continue with

By registering, you agree to our Terms of Service and you acknowledge that you have read and understand our Privacy Policy .

Root Cause Analysis – The 5 Whys Technique

This elementary and often effective approach to problem-solving promotes deep thinking through questioning, and can be adapted quickly and applied to most problems. For example, asking “Why?” may be a favorite technique of your three-year-old child in driving you crazy, but it could teach you a valuable problem-solving technique.

“If you don’t ask the right questions, you don’t get the right answers. A question asked in the right way often points to its answer. Asking questions is the ABC of diagnosis. Only the inquiring mind solves problems.” – Edward Hodnett

The “5 Whys” is a simple problem-solving technique that helps you to get to the root of a problem quickly, which was originally developed by Sakichi Toyota. It was used within the Toyota Motor Corporation during the evolution of its manufacturing methodologies. It is a critical component of problem-solving training, delivered as part of the induction into the Toyota Production System.

How to Conduct 5 Whys Analysis?

When you’re looking to solve a problem, start at the result and work backward (toward the root cause), continually asking: “Why?” You’ll need to repeat this over and over until the root cause of the problem becomes apparent.

The 5 Whys strategy involves looking at any problem and asking: “Why?” and “What caused this problem?” Very often, the answer to the first “why” will prompt another “why” and the answer to the second “why” will prompt another and so on; hence the name the 5 Whys strategy.

The 5 Whys exercise is vastly improved when applied by a team and there are five basic steps to conducting it:

- Write down the specific problem. Writing the issue helps you formalize the problem and describe it completely. It also helps a team focus on the same problem.

- Ask “Why” the problem happens and write the answer down below the problem.

- If the answer you just provided doesn’t identify the root cause of the problem that you wrote down in Step 1, ask “Why” again and write that answer down.

- Loopback to step 3 until the team is in agreement that the problem’s root cause is identified. Again, this may take fewer or more times than five Whys.

- After settling on the most probable root cause of the problem and obtaining confirmation of the logic behind the analysis, develop appropriate corrective actions to remove the root cause from the system.

Edit this Diagram

5 Whys Example

The vehicle will not start. (The problem)

- Why? – The battery is dead. (First why)

- Why? – The alternator is not functioning. (Second why)

- Why? – The alternator belt has broken. (Third why)

- Why? – The alternator belt was well beyond its useful service life and not replaced. (Fourth why)

- Why? – The vehicle was not maintained according to the recommended service schedule. (Fifth why, a root cause)

Note: A 5 Whys analysis sometime could be taken further to a sixth, seventh, or higher level, but five iterations of asking why are generally sufficient to get to a root cause.

5-Whys Criticisms

Here are each of the criticisms as listed on the Wikipedia:

- Stopping at symptoms, not the root cause

- Limited by the investigator’s knowledge.

- Not asking the right Why questions.

- Not repeatable – Different people build different 5 Whys.

- The tendency to isolate a single root cause

©2024 by Visual Paradigm. All rights reserved.

- Terms of Service

- Privacy Policy

- Security Overview

The Power of the Five Whys: Drilling Down to Effectively Problem-Solve

It’s a fact of life that things don’t always go according to plan. When facing mistakes or challenges, asking “why”—especially if you do it repeatedly—can help uncover deeper layers of understanding so you can identify potential solutions.