500+ business plans and financial models

Manufacturing Business Plan PDF Example

- May 7, 2024

- Business Plan

Creating a comprehensive business plan is crucial for launching and running a successful manufacturing business. This plan serves as your roadmap, detailing your vision, operational strategies, and financial plan. It helps establish your manufacturing business’s identity, navigate the competitive market, and secure funding for growth.

This article not only breaks down the critical components of a manufacturing business plan, but also provides an example of a business plan to help you craft your own.

Whether you’re an experienced entrepreneur or new to the manufacturing industry, this guide, complete with a business plan example, lays the groundwork for turning your manufacturing business concept into reality. Let’s dive in!

Our manufacturing business plan covers all essential aspects necessary for a comprehensive strategy. It details operations, marketing strategy , market environment, competitors, management team, and financial forecasts.

- Executive Summary : Provides an overview of the manufacturing company’s business concept, market analysis , management, and financial strategy.

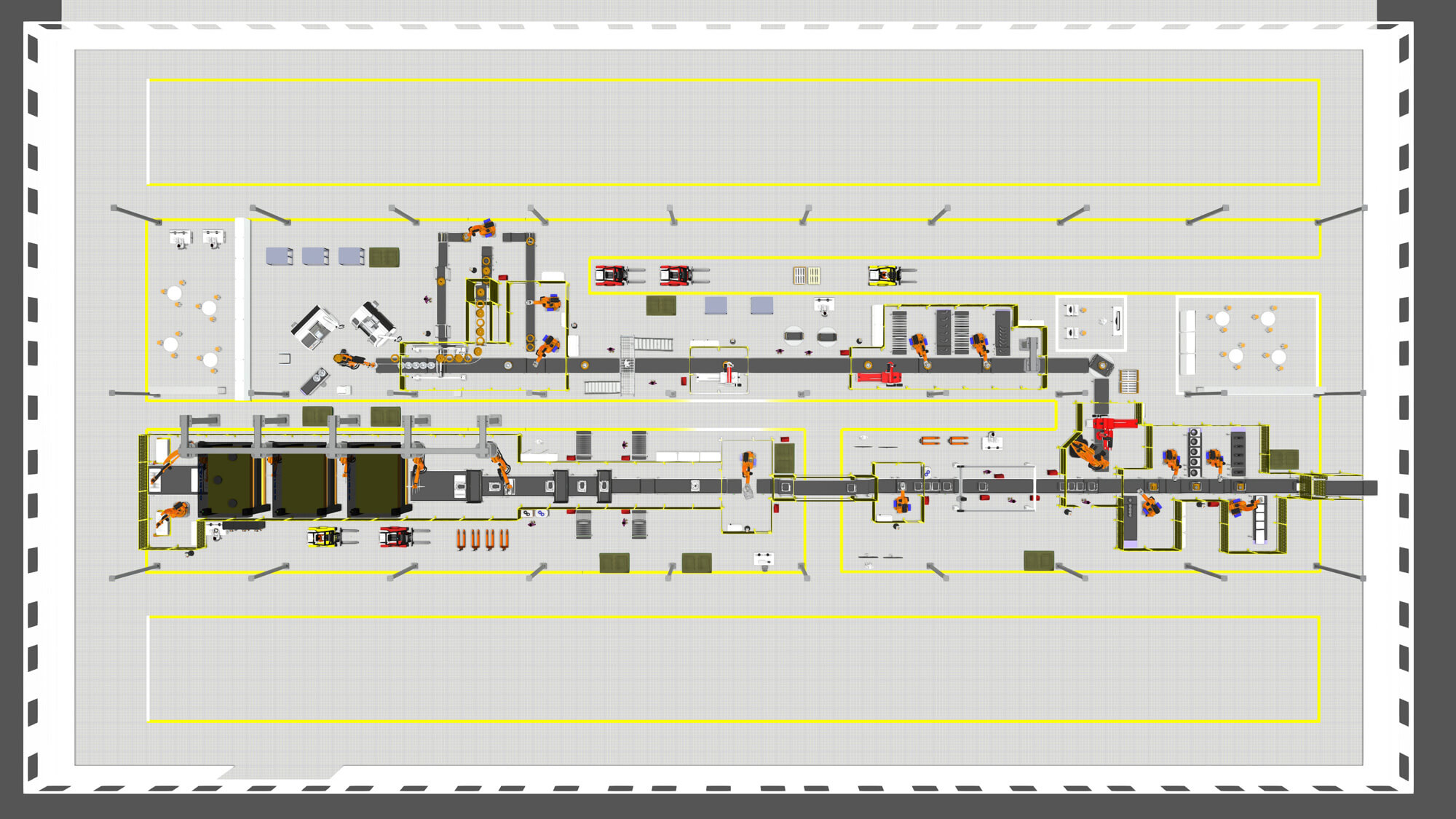

- Facilities & Equipment: Describes the facility’s capabilities, machinery, and technological advancements.

- Operations & Supply: Outlines the production processes, supply chain logistics, and inventory management.

- Key Stats: Offers data on industry size , growth trends, and market positioning.

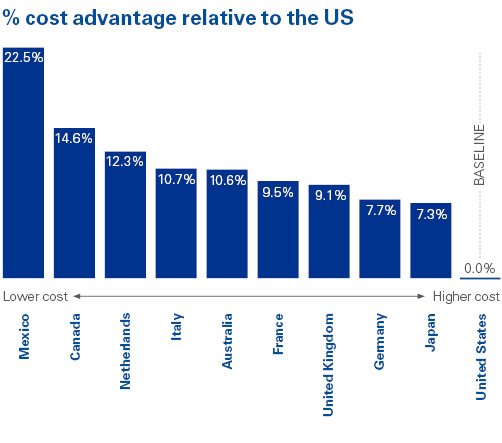

- Key Trends: Highlights significant trends impacting the industry, such as automation and localization.

- Key Competitors : Analyzes primary competitors and differentiates the company from these rivals.

- SWOT: Analyzes strengths, weaknesses, opportunities, and threats.

- Marketing Plan : Outlines tactics for attracting new contracts and maintaining client relationships.

- Timeline : Sets out key milestones from inception through the first year of operations.

- Management: Information on the management team and their roles within the company.

- Financial Plan: Projects the company’s financial performance over the next five years, detailing revenue, profits, and anticipated expenses.

Manufacturing Business Plan

Fully editable 30+ slides Powerpoint presentation business plan template.

Download an expert-built 30+ slides Powerpoint business plan template

Executive Summary

The Executive Summary introduces your manufacturing business plan, offering a concise overview of your manufacturing facility and its products. It should detail your market positioning, the range of products manufactured, the production process, its location, size, and an outline of day-to-day operations.

This section should also explore how your manufacturing business will integrate into the local and broader markets, including the number of direct competitors within the area, identifying who they are, along with your business’s unique selling points that differentiate it from these competitors.

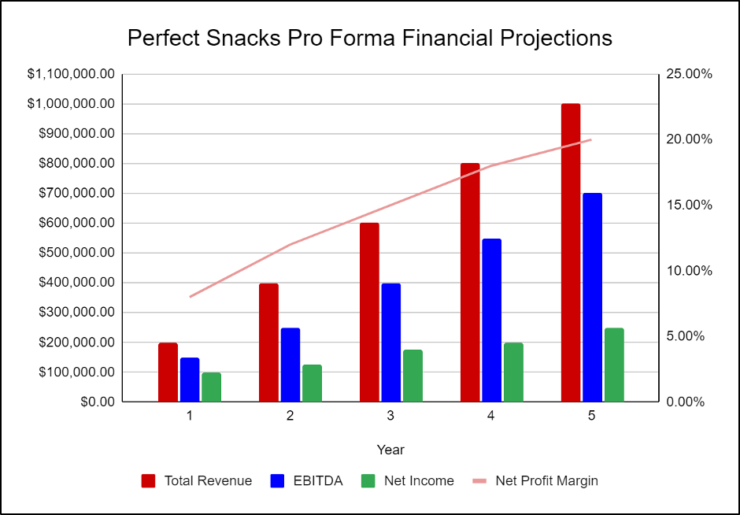

Furthermore, you should include information about the management and co-founding team, detailing their roles and contributions to the business’s success. Additionally, a summary of your financial projections, including revenue and profits over the next five years, should be presented here to provide a clear picture of your business’s financial plan.

Make sure to cover here _ Business Overview _ Market Overview _ Management Team _ Financial Plan

Dive deeper into Executive Summary

Business Overview

Facilities & equipment.

Describe your manufacturing facility. Highlight its design, capacity, and technology. Mention the location, emphasizing accessibility to transport routes. Discuss advantages for efficiency and cost management. Detail essential equipment and its capabilities.

Operations & Supply Chain

Detail product range. Outline your operations strategy for efficiency and scalability. Discuss supply chain management. Highlight sourcing of materials, inventory control, and logistics. Emphasize strong partnerships with suppliers and distributors.

Make sure to cover here _ Facilities & Equipment _ Operations & Supplies

Market Overview

Industry size & growth.

Start by examining the size of the manufacturing industry relevant to your products and its growth potential. This analysis is crucial for understanding the market’s scope and identifying expansion opportunities.

Key Market Trends

Proceed to discuss recent market trends , such as the increasing demand for sustainable manufacturing processes, automation, and advanced materials. For example, highlight the demand for products that utilize eco-friendly materials or energy-efficient production techniques, alongside the rising popularity of smart manufacturing.

Key Competitors

Then, consider the competitive landscape, which includes a range of manufacturers from large-scale enterprises to niche firms. For example, emphasize what makes your business distinctive, whether it’s through advanced technology, superior product quality, or specialization in certain manufacturing niches. This section will help articulate the demand for your products, the competitive environment, and how your business is positioned to thrive within this dynamic market.

Make sure to cover here _ Industry size & growth _ Key competitors _ Key market trends

Dive deeper into Key competitors

First, conduct a SWOT analysis for your manufacturing business. Highlight Strengths such as advanced production technology and a skilled workforce. Address Weaknesses, including potential supply chain vulnerabilities or high production costs. Identify Opportunities like emerging markets for your products or potential for innovation in production processes. Consider Threats such as global competition or economic downturns that may impact demand for your products.

Marketing Plan

Next, develop a marketing strategy that outlines how to attract and retain customers through targeted advertising, trade shows, digital marketing, and strategic partnerships. Emphasize the importance of showcasing product quality and technological advantages to differentiate your business in the market.

Finally, create a detailed timeline that outlines critical milestones for your manufacturing business’s launch, marketing initiatives, customer acquisition, and expansion goals. Ensure the business progresses with clear direction and purpose, setting specific dates for achieving key operational and sales targets.

Make sure to cover here _ SWOT _ Marketing Plan _ Timeline

Dive deeper into SWOT

Dive deeper into Marketing Plan

The Management section focuses on the manufacturing business’s management and their direct roles in daily operations and strategic direction. This part is crucial for understanding who is responsible for making key decisions and driving the manufacturing business toward its financial and operational goals.

For your manufacturing business plan, list the core team members, their specific responsibilities, and how their expertise supports the business.

Financial Plan

The Financial Plan section is a comprehensive analysis of your financial projections for revenue, expenses, and profitability. It lays out your manufacturing business’s approach to securing funding, managing cash flow, and achieving breakeven.

This section typically includes detailed forecasts for the first 5 years of operation, highlighting expected revenue, operating costs and capital expenditures.

For your manufacturing business plan, provide a snapshot of your financial statement (profit and loss, balance sheet, cash flow statement), as well as your key assumptions (e.g. number of customers and prices, expenses, etc.).

Make sure to cover here _ Profit and Loss _ Cash Flow Statement _ Balance Sheet _ Use of Funds

Privacy Overview

- See all articles

- Business tips

- Inventory management

- Manufacturing

- Product updates

Getting started: A guide to creating a manufacturing business plan

Every day people are trying and failing at entrepreneurism.

The journey is a difficult one, and the chances of success are slim. Those that succeed sometimes have a brilliant idea, while others have a wealth of resources. The one commonality among all successful entrepreneurs is that they had a manufacturing business plan.

You need to know where you are going, how you will get there, and what you will do when you arrive. This is especially important for those in the manufacturing industry because of the significant amount of forethought required.

Even if you are leveraging digital solutions to minimize the amount of time, money, and effort required to bring your product to market, you will still need a plan. This is not an area where you can wing it and hope for the best.

Below, we will examine the basics of a manufacturing business plan, what is necessary to include, how to create one for your own company, and some common mistakes that you should avoid.

Table of contents:

What is a manufacturing business plan, why does a manufacturing company need a business plan, what are the key components of a business plan, how to write a business plan for a manufacturing company, common mistakes to avoid.

A manufacturing business plan is a formal document that outlines the goals and objectives of your business. It includes detailed information about your:

- Products or services

- Target market

- Marketing strategy

- Financial projections

- Operational details

The purpose of a business plan is to give you a roadmap to follow as you build and grow your business. It forces you to think through every aspect of your venture and identify potential problems or roadblocks before they happen.

Manufacturing business plans can also be used to attract investors or secure funding from lenders. If you are looking for outside financing, your business plan needs to be even more detailed and include information on your management team, financial history, and expected growth.

Ideally, you should update your business plan yearly to ensure that it remains relevant and accurate. As your business grows and changes, so too should your plan.

No matter how simple or complex your ideas may be, you need a plan, or they will never become a reality. A business plan will clearly understand your costs, competition, and target market. It will also help you to set realistic goals and track your progress over time.

Let’s look at a manufacturing strategy example. You have a great idea that you think will revolutionize the automotive industry . Your new safety harness will be made from a lightweight, yet incredibly strong, material that cannot be cut or torn. You are confident that your product will be in high demand and generate a lot of revenue.

But before you walk into Ford or Toyota to try and get a purchase order , you need to have a plan. You must know:

- How much will it cost to produce your product

- How many units do you need to sell to break even

- Who is your target market is

- What is your competition selling

- How will you reach your target market

You also need to clearly understand the regulatory landscape and what it takes to bring a new product to market. All of this information (and more) should be included in your business plan.

This is not just a document that you create and forget about. It is a living, breathing tool that should be used to guide your actions as you build and grow your business.

Every manufacturing business plan will be different, but almost always, they will include the same five components:

Executive summary

Company description, products and services, market analysis.

- Financial plan

Let’s take a closer look.

The executive summary is the first section of your business plan, but it is typically written last. This is because it should be a concise overview of everything that follows, and you can only do that once you have completed the rest of your plan.

Include the following in your executive summary:

- The problem that your product or service solves

- Your target market

- Your unique selling proposition (what makes you different from your competitors?)

- Your manufacturing business model (how will you make money?)

- Your sales and marketing strategy

- A brief overview of your financial projections

Someone should be able to quickly scan through your executive summary and have a pretty good understanding of what your business is and how it plans to be successful.

This is where you can get a bit more creative, explaining your company’s history, mission, and values. You will also include information on your team or management structure.

It can be simple but should inspire faith in your ability to execute your business plan.

You will need to provide a detailed description of your product or service, as well as any unique features or benefits that it offers. You should also include information on your manufacturing process and quality control procedures.

If you have any patents or proprietary technology, they should be listed here as significant assets for your business.

For example, let’s say you are planning on creating a brand-new line of disposable coffee cups. The dimensions, materials, and other specifications would be listed here, along with any unique benefits (such as being made from recycled materials).

You might also include information on your manufacturing process, such as the fact that the cups will be produced in a certified clean room or that you will employ workers local to where the product is sold.

Chances are, you started down this path because you realized that there was a market opportunity for your product or service. In this section, you will need to provide detailed information on the opening, as well as the analysis that convinced you to pursue it.

This should include:

- Market size (current and projected)

- Key market segments

- Customer needs and wants

- Competitive landscape

This is where you will need to do your homework, as you will be justifying your business decision to enter this particular market. The more data and analysis you can provide, the better.

For our coffee cup example, the market analysis might include:

- Information on how many cups are used every day

- Projected growth

- Key segments (such as office workers or on-the-go consumers)

- Customer needs (such as convenience or sustainability)

It would also examine the competitive landscape, including both direct and indirect competitors.

Financial plan

You’re in this to make money, and so are your potential investors. In this section, you will need to provide detailed information on your manufacturing business model and how it will generate revenue. This should include:

- Initial investment

- Sales forecast

- Carrying costs

- Pricing strategy

- Expense budget

You will also need to provide information on your long-term financial goals, such as profitability or break-even point. Discuss production line details, inventory management strategies , and other factors impacting your bottom line.

The process of creating a business plan for a manufacturing company is similar to any other type of business. However, there are some key considerations to keep in mind.

First, you need to understand your industry and what it will take to be successful in it. This includes understanding the competitive landscape, the costs of goods sold , and the margins you can expect to achieve.

You also need to have a clear understanding of your target market and what needs or wants your product or service will address. This market analysis should include information on your target customer’s demographics, psychographics, and buying habits.

While there will be many things specific to your company, here are five questions to answer for each of the sections listed above.

Executive summary:

- What is the problem that your company will solve?

- How will your company solve that problem?

- Who are your target customers?

- What are your key competitive advantages?

- What is your business model?

Company description:

- What is the legal structure of your company?

- What are your company’s core values?

- What is your company’s history?

- Who are the key members of your management team?

- Where is your manufacturing facility located?

Products and services:

- What product or service does your company offer?

- How does your product or service solve the problem that your target market has?

- What are the key features and benefits of your product or service?

- How is your product or service unique from your competitors?

- What is the production process for your product or service?

Market analysis:

- Who is your target market?

- What needs or wants does your target market have that your product or service will address?

- What is the size of your target market?

- How do you expect the needs of your target market to change in the future?

- Who are your key competitors, and how do they serve the needs of your target market?

Financial plan:

- What are the start-up costs for your company?

- How will you finance your start-up costs?

- What are your monthly operating expenses?

- What is your sales forecast for the first year, and how does that compare to your industry’s average sales growth rate?

- What are your gross margin and profit targets?

Even if you do nothing but answer these questions, you’ll be well on your way to creating a thorough manufacturing business plan.

How to stabilize your growth

However, new manufacturing entrepreneurs often fall into a handful of traps when creating their business plans.

- Not doing enough research – You can’t know everything about your industry, but you should do your best to understand as much as you can before writing your business plan. This means talking to experts, reading trade publications, and studying the competition

- Not being realistic – It’s important to be optimistic when starting a new business, but you also need to be realistic. This is especially true when it comes to financial projections. Don’t overestimate the amount of revenue you will generate or underestimate the costs of goods sold

- Not having a clear understanding of your target market – You need to know who you are selling to and what needs or wants your product or service will address. This market analysis should include information on your target customer’s demographics, psychographics, and buying habits

- Failing to understand your competition – You need to know who your competitors are, what they are offering, and how you can differentiate yourself. This information will be critical in developing your marketing strategy

- Not having a clear vision for the future – Your manufacturing business plan should include a section on your long-term goals and objectives. What does your company hope to achieve in the next five years? Ten years? Twenty years?

Creating a business plan for manufacturing can be simple. It can be quite simple if you break it down into smaller pieces.

Once you have it in place, staying on track can be quite a bit more difficult. By using ERP software like Katana , you can track all of your key metrics in real time, avoid any potential issues, and make course corrections as needed.

To start following your plan and creating a successful manufacturing company, get a Katana demo today.

- Manufacturing guide

- 1.1. Production vs manufacturing

- 1.2. Production scheduling software

- 1.3. Production tracking software

- 2.1. How to manufacture a product

- 2.2. Manufacturing best practices

- 2.3. A guide to creating a manufacturing business plan

- 2.4. Manufacturer e-commerce

- 2.5. Marketing for manufacturers

- 2.6. Manufacturing business processes

- 2.7. Food manufacturing

- 2.8. Small business manufacturing software

- 3.1. Job shop manufacturing

- 3.2. Production quality control checklist

- 4.1. Just-in-time (JIT) manufacturing

- 4.2. Tips to reduce manufacturing waste

- 4.3. Manufacturing KPIs

- 5. Light manufacturing

- 6. Advanced manufacturing

- 7. IoT in manufacturing

- 8.1. Manufacturing execution system (MES)

- 9.1. Manufacturing overhead formula

- 9.2. Manufacturing inventory software

- 10. Good manufacturing practices (GMP)

- 11.1. MRP in supply chain management

- 11.2. Best MRP software

- 12.1. Best ERP software for manufacturing

More guides from Katana

Manufacturing Business Plan Template

Written by Dave Lavinsky

Manufacturing Business Plan

You’ve come to the right place to create your Manufacturing business plan.

We have helped over 1,000 entrepreneurs and business owners create business plans and many have used them to start or grow their Manufacturing companies.

Below is a template to help you create each section of your Manufacturing business plan.

Executive Summary

Business overview.

Perfect Snacks, located in Lincoln, Nebraska, is a food manufacturing company that specializes in the production of snack foods and packaged goods. We manufacture an extensive line of snack products, including trail mix, gummies, and chocolate. Our company focuses on quality and only uses the best natural ingredients in our products. We will primarily sell our products to grocery stores and other establishments that sell snacks, but will also sell bulk orders to individual customers through our website.

Perfect Snacks was founded by Joe Boseley. Joe has been working on the manufacturing company concept over the past few years and began networking with grocery store clients and locating the land to build his manufacturing and distribution center. As a line manager that oversaw dozens of employees, Joe has the proper knowledge and experience to own, manage, and operate his own manufacturing company.

Product Offering

Perfect Snacks will manufacture an extensive list of sweet, salty, and healthy snacks. Some of our initial products will include:

We will primarily sell our products to grocery stores, recreation centers, and other businesses that sell snacks in bulk. Consumers can find our products in stores or buy them in bulk on our website.

Customer Focus

Perfect Snacks will primarily serve the residents of Lincoln, Nebraska. The community has a large population of families and children, who are the primary consumers of snack foods. Therefore, we will market our products to recreational centers, schools, grocery stores, and other establishments that sell snacks to children and their parents.

Management Team

Perfect Snacks is owned by Joe Boseley, a local entrepreneur who has worked in various warehouses and manufacturing companies in Lincoln, Nebraska. Working in the manufacturing industry and in warehouses, Joe is very familiar with the processing and distribution of packaged foods. As a line manager that oversaw dozens of employees, Joe has the proper knowledge and experience to own, manage, and operate his own manufacturing company.

Joe will utilize his past experience with developing staff roles and functions. He is also very familiar with the manufacturing equipment and plans to purchase the latest technology that is efficient and cost effective. His contacts have allowed him to gain concrete Letters of Intent from local supermarket chains to have his manufactured goods in their stores.

Success Factors

Perfect Snacks will be able to achieve success by offering the following competitive advantages:

- Taste: Perfect Snacks’ snack products will be made with the highest quality ingredients and offer quality over quantity.

- Price: Perfect Snacks is able to offer the highest quality snacks at a competitive price point.

- Community Relations: Perfect Snacks will be a pillar in the community and be heavily involved in family-related activities in the area. It will sponsor events, provide snacks for schools and daycares at a discounted price, and donate a portion of its proceeds to area family-related charities and organizations.

- Proprietary Technology: Perfect Snacks will invest heavily on the latest technology to manufacture the snack foods for distribution. It will ensure the food products are made safely and free from any harmful chemicals and ingredients.

Financial Highlights

Perfect Snacks is seeking a total funding of $1,200,000 of debt capital to open its manufacturing company. The capital will be used for funding capital expenditures, salaries, marketing expenses, and working capital. Specifically, these funds will be used as follows:

- Manufacturing facility design/build-out: $400,000

- Equipment and supplies: $375,000

- Initial inventory: $100,000

- Three months of overhead expenses (payroll, rent, utilities): $250,000

- Marketing costs: $50,000

- Working capital: $25,000

The following graph below outlines the pro forma financial projections for Perfect Snacks.

Company Overview

Who is perfect snacks, perfect snacks history.

After conducting a market analysis, Joe Boseley began surveying the local vacant warehouse space and decided on a parcel of land to construct the warehouse and distribution center. Joe incorporated Perfect Snacks as a Limited Liability Corporation on January 1st, 2023.

Once the land is acquired for the warehouse space, construction can begin to build-out the manufacturing facility.

Since incorporation, the Company has achieved the following milestones:

- Located a vacant lot that would be ideal for a manufacturing facility

- Developed the company’s name, logo, and website

- Hired a general contractor and architect for the build-out of the warehouse, small office, and distribution area

- Determined equipment and necessary supplies

- Determined beginning inventory

- Attained Letters of Intent from supermarket clients

- Began recruiting key employees

Perfect Snacks Services

Industry analysis.

The Manufacturing sector’s performance is largely attributable to the value of the US dollar, commodity prices, policy decisions and US manufacturing capacity. Food manufacturing has a history of success as it produces a basic human need. According to Grand View Research, the industry is currently valued at $121 billion and is expected to expand at a compound annual growth rate of 9.5% from now until 2030.

Commodity prices are currently stabilizing from coronavirus-induced volatility and renewed demand, both in the United States and global economies, which is anticipated to facilitate revenue expansion for manufacturers. Moreover, shifting technological change in the Manufacturing sector is anticipated to benefit large, developed economies, such as the United States. Therefore, now is a great time to start a new food manufacturing company in the U.S.

Customer Analysis

Demographic profile of target market.

Perfect Snacks will serve the community residents of Lincoln, Nebraska and its surrounding areas. The community of Lincoln, Nebraska has thousands of households that have children. Statistics show that the main consumers of snack products are children of all ages. They are regularly placed in school lunchboxes, afterschool snacks and programs, and at weekend sporting events. Therefore, we will market to locations where snacks are bought by children or their parents, such as grocery stores, recreational centers, and schools.

The precise demographics Lincoln, Nebraska is as follows:

Customer Segmentation

Perfect Snacks will primarily target the following customer profiles:

- Grocery stores and recreational centers

Competitive Analysis

Direct and indirect competitors.

Perfect Snacks will face competition from other companies with similar business profiles. A description of each competitor company is below.

Snacks N More

Snacks N More is another local manufacturing company that provides snack food to the immediate area. Established over thirty years ago, the company has the knowledge and expertise in food processing, commercialization, and packaging. They are known as a recognized ingredient supplier for the foodservice industry. Their portfolio of products include a variety of nuts, snacks, confections, and dry-blend ingredients. As a private label manufacturer, Snack’s More produces a full line of non-chocolate candy, nuts, and fruit-flavored snacks. The company is known for their fruit flavored snacks, dried raisins, nut mixes, and producing ingredients for local restaurants and establishments. Their line of nuts and dried fruits are often used for baking purposes.

Jaxon’s Candy

Jaxon’s Candy is a manufacturer of all things candy related. As a contract manufacturer, the company works with many companies to create their custom designed confections. Their large 50,000 square foot facility produces over 300,000 pounds of candy every month. All of the products are highly concentrated either in sugar or chocolate, or both. Jaxon’s Candy also designs and manufactures their own custom packaging. The candy produced is also kosher certified, gluten free, peanut free, and non-GMO.

Jaxon’s Candy currently manufactures candy for the following brands – Tommy Candy, Laffy Town, Chocowhoawhoa, Jellylicious, Healthee Candeee, and Sticky Teeth. Jaxon’s Candy can be found in grocery stores and convenient stores along the west coast of the United States.

Gimmy Candy

Gimmy Candy is located in the midwestern portion of the United States and boasts a facility of over 1 million square feet. Their fleet of transportation trucks distributes throughout the continental United States and is considered one of the largest candy manufacturers in the country. Their product portfolio includes assorted chocolates, gummy candy, hard candy, fruit candy, as well as gums and mints. Gimmy Candy was established in 1947 and has grown to be a model of manufacturing companies the industry uses as a model of sustainability and profitability. Their lineup of candy products can be found in every single grocery store and convenient store in the country. Gimmy Candy is considering expanding its distribution globally and start exporting its candy products to Asia, Canada, Europe, and South America. As one of the largest privately held companies in the United States, Gimmy Candy is also considered a top employer in the country and offers its employees a generous benefits package.

Competitive Advantage

Perfect Snacks will be able to offer the following advantages over their competition:

Marketing Plan

Brand & value proposition.

Perfect Snacks will offer the unique value proposition to its clientele:

- Fresh and comforting taste

- Community family advocate

- Developed with proprietary technology

- Manufactured with fresh, quality ingredients

- Affordable price

Promotions Strategy

The promotions strategy for Perfect Snacks is as follows:

Social Media

Perfect Snacks will invest heavily in a social media advertising campaign. The brand manager will create the company’s social media accounts and invest in ads on all social media accounts. It will use targeted marketing to appeal to the target demographics.

Website/SEO

Perfect Snacks will invest heavily in developing a professional website that displays all of the features and benefits of the snack products. It will also invest heavily in SEO so that the brand’s website will appear at the top of search engine results.

Major Publications

We will also invest in advertising in selected larger publications until we have achieved significant brand awareness. Advertisements such as billboards and commercials will be shown during peak tv watching time and the billboards will be placed in highly trafficked areas.

Sponsorships

Perfect Snacks will also invest in sponsoring certain athletic and school events so that their banners and collateral material are displayed all over the event where numerous parents and children are at.

Perfect Snacks’s pricing will be moderate so consumers feel they receive great value when purchasing our snack products.

Operations Plan

The following will be the operations plan for Perfect Snacks.

Operation Functions:

- Joe Boseley will be the CEO of Perfect Snacks. He will oversee the general operations and executive aspects of the business.

- Joe is joined by Candace Smith who will act as the warehouse manager. She will train and manage the staff as well as oversee general production of our products.

- Joe will hire an Administrative Assistant, Marketing Manager, and Accountant, to handle the administrative, marketing, and bookkeeping functions of the company.

- Joe will also hire several employees to manufacture our products and maintain the equipment and machinery.

Milestones:

Perfect Snacks will have the following milestones complete in the next six months.

- 02/202X Finalize lease agreement

- 03/202X Design and build out Perfect Snacks

- 04/202X Hire and train initial staff

- 05/202X Kickoff of promotional campaign

- 06/202X Launch Perfect Snacks

- 07/202X Reach break-even

Financial Plan

Key revenue & costs.

Perfect Snacks’s revenues will come primarily from its snack food sales. The company will sell the packaged snacks in local grocery stores, convenience stores, and other locations. As the company’s revenues increase, it will look to gain a wider distribution area.

The land purchase, equipment, supplies, opening inventory, and labor expenses will be the key cost drivers of Perfect Snacks. Other cost drivers include taxes, business insurance, and marketing expenditures.

Funding Requirements and Use of Funds

Key assumptions.

The following outlines the key assumptions required in order to achieve the revenue and cost numbers in the financials and pay off the startup business loan.

- Average order value: $250

Financial Projections

Income statement, balance sheet, cash flow statement, manufacturing business plan faqs, what is a manufacturing business plan.

A manufacturing business plan is a plan to start and/or grow your manufacturing business. Among other things, it outlines your business concept, identifies your target customers, presents your marketing plan and details your financial projections.

You can easily complete your Manufacturing business plan using our Manufacturing Business Plan Template here .

What are the Main Types of Manufacturing Businesses?

There are a number of different kinds of manufacturing businesses , some examples include: Garment manufacturing, Food product manufacturing, Diaper manufacturing, Tile manufacturing, and Toy manufacturing.

How Do You Get Funding for Your Manufacturing Business Plan?

Manufacturing businesses are often funded through small business loans. Personal savings, credit card financing and angel investors are also popular forms of funding.

What are the Steps To Start a Manufacturing Business?

Starting a manufacturing business can be an exciting endeavor. Having a clear roadmap of the steps to start a business will help you stay focused on your goals and get started faster.

1. Develop A Manufacturing Business Plan - The first step in starting a business is to create a detailed manufacturing business plan that outlines all aspects of the venture. This should include potential market size and target customers, the services or products you will offer, pricing strategies and a detailed financial forecast.

2. Choose Your Legal Structure - It's important to select an appropriate legal entity for your manufacturing business. This could be a limited liability company (LLC), corporation, partnership, or sole proprietorship. Each type has its own benefits and drawbacks so it’s important to do research and choose wisely so that your manufacturing business is in compliance with local laws.

3. Register Your Manufacturing Business - Once you have chosen a legal structure, the next step is to register your manufacturing business with the government or state where you’re operating from. This includes obtaining licenses and permits as required by federal, state, and local laws.

4. Identify Financing Options - It’s likely that you’ll need some capital to start your manufacturing business, so take some time to identify what financing options are available such as bank loans, investor funding, grants, or crowdfunding platforms.

5. Choose a Location - Whether you plan on operating out of a physical location or not, you should always have an idea of where you’ll be based should it become necessary in the future as well as what kind of space would be suitable for your operations.

6. Hire Employees - There are several ways to find qualified employees including job boards like LinkedIn or Indeed as well as hiring agencies if needed – depending on what type of employees you need it might also be more effective to reach out directly through networking events.

7. Acquire Necessary Manufacturing Equipment & Supplies - In order to start your manufacturing business, you'll need to purchase all of the necessary equipment and supplies to run a successful operation.

8. Market & Promote Your Business - Once you have all the necessary pieces in place, it’s time to start promoting and marketing your manufacturing business. This includes creating a website, utilizing social media platforms like Facebook or Twitter, and having an effective Search Engine Optimization (SEO) strategy. You should also consider traditional marketing techniques such as radio or print advertising.

Manufacturing Business Plan Template [Updated 2024]

Manufacturing Business Plan Template

If you want to start a Manufacturing business or expand your current Manufacturing company, you need a business plan.

The following Manufacturing business plan template gives you the key elements to include in a winning Manufacturing business plan.

You can download our business plan template (including a full, customizable financial model) to your computer here.

Below are links to each of the key sections of a sample manufacturing business plan. Once you create your plan, download it to PDF to show banks and investors.

I. Executive Summary II. Company Overview III. Industry Analysis IV. Customer Analysis V. Competitive Analysis VI. Marketing Plan VII. Operations Plan VIII. Management Team IX. Financial Plan

Comments are closed.

Manufacturing Business Plan Home I. Executive Summary II. Company Overview III. Industry Analysis IV. Customer Analysis V. Competitive Analysis VI. Marketing Plan VII. Operations Plan VIII. Management Team IX. Financial Plan

- Business planning and strategy

Manufacturing Business: Business Plan Example

Are you setting up a manufacturing business? We’ve created an example business plan to help you get started.

Are you manufacturing goods from home? Want to move to the next level and ramp up your business’ production? Starting to write a business plan will help you identify your markets, outline potential risks and understand the cash flow for your business.

To help you get started we’ve created an example business plan for the manufacturing industry. Our example focuses on producing high quality leather accessories, but it will work as a framework regardless of the specific business you are considering. Click the Download button to gain access to the word document.

Good luck and happy writing!

Related resources

- Entrepreneurship

Manufacturing Business Plan Template

What is a Manufacturing Business Plan?

A manufacturing business plan outlines the objectives, initiatives, and goals of a manufacturing business. It is used to guide the development and execution of a business strategy and to monitor progress towards achieving desired goals. The plan should address all aspects of the business, including marketing, production, personnel, operations, and financials.

What's included in this Manufacturing Business Plan template?

- 3 focus areas

- 6 objectives

Each focus area has its own objectives, projects, and KPIs to ensure that the strategy is comprehensive and effective.

Who is the Manufacturing Business Plan template for?

This Manufacturing Business Plan template is designed to help manufacturers of all sizes and industries create a plan to launch, run and grow their business. It provides a framework to clearly define and measure the objectives, actions, and measurements that are necessary for success.

1. Define clear examples of your focus areas

A focus area is an area of your business that requires extra attention in order to achieve success. Examples of focus areas can include increasing operational efficiency, improving product quality, or strengthening financial management.

2. Think about the objectives that could fall under that focus area

An objective is a goal that you want to achieve within a specific focus area. For example, under the focus area of operational efficiency, the objective could be to reduce shipping wait time.

3. Set measurable targets (KPIs) to tackle the objective

KPIs, or key performance indicators, are metrics that help to measure the success of the objectives. For example, to measure the success of the objective to reduce shipping wait time, the KPI would be to decrease the average shipping wait time by 30%.

4. Implement related projects to achieve the KPIs

Projects, or actions, are the steps necessary to achieve the KPIs. For example, to achieve the KPI of reducing the average shipping wait time, the action would be to analyze the current shipping process.

5. Utilize Cascade Strategy Execution Platform to see faster results from your strategy

Cascade is a strategy execution platform that makes it easy to plan, implement, and track progress towards achieving your manufacturing business plan. With Cascade, you can create strategies, assign tasks, track progress, and quickly see the results of your efforts.

Plastic Manufacturing Business Plan Template & Guidebook

Are you interested in starting your own plastic manufacturing company but unsure of where to start? We can assist you with our plastic manufacturing business plan template and how-to manual. You can simply construct a business plan that details every facet of your enterprise, from market analysis and financial predictions to marketing plans and operational tactics, with the help of our comprehensive template and professional advice. Making your concept a reality is simple with our step-by-step process for starting a profitable plastic manufacturing company. With the help of our tried-and-true template and direction, you can confidently start the process of creating a successful plastic manufacturing company. Join the ranks of prosperous plastic manufacturing businesses by getting started right away!

Get worry-free services and support to launch your business starting at $0 plus state fees.

- How to Start a Profitable Plastic Manufacturing Business [11 Steps]

- 25 Catchy Plastic Manufacturing Business Names:

- List of the Best Marketing Ideas For Your Plastic Manufacturing Business:

How to Write a Plastic Manufacturing Business Plan in 7 Steps:

1. describe the purpose of your plastic manufacturing business..

The first step to writing your business plan is to describe the purpose of your plastic manufacturing business. This includes describing why you are starting this type of business, and what problems it will solve for customers. This is a quick way to get your mind thinking about the customers’ problems. It also helps you identify what makes your business different from others in its industry.

It also helps to include a vision statement so that readers can understand what type of company you want to build.

Here is an example of a purpose mission statement for a plastic manufacturing business:

Our mission is to produce high-quality, cost-effective plastic that meets the needs of our customers. We will accomplish this by providing a safe work environment for our employees and investing in the latest equipment. We will also ensure that all stakeholders are treated with respect and value their input in order to make sure we’re always making the best decisions possible.

2. Products & Services Offered by Your Plastic Manufacturing Business.

The next step is to outline your products and services for your plastic manufacturing business.

When you think about the products and services that you offer, it's helpful to ask yourself the following questions:

- What is my business?

- What are the products and/or services that I offer?

- Why am I offering these particular products and/or services?

- How do I differentiate myself from competitors with similar offerings?

- How will I market my products and services?

You may want to do a comparison of your business plan against those of other competitors in the area, or even with online reviews. This way, you can find out what people like about them and what they don’t like, so that you can either improve upon their offerings or avoid doing so altogether.

3. Build a Creative Marketing Stratgey.

If you don't have a marketing plan for your plastic manufacturing business, it's time to write one. Your marketing plan should be part of your business plan and be a roadmap to your goals.

A good marketing plan for your plastic manufacturing business includes the following elements:

Target market

- Who is your target market?

- What do these customers have in common?

- How many of them are there?

- How can you best reach them with your message or product?

Customer base

- Who are your current customers?

- Where did they come from (i.e., referrals)?

- How can their experience with your plastic manufacturing business help make them repeat customers, consumers, visitors, subscribers, or advocates for other people in their network or industry who might also benefit from using this service, product, or brand?

Product or service description

- How does it work, what features does it have, and what are its benefits?

- Can anyone use this product or service regardless of age or gender?

- Can anyone visually see themselves using this product or service?

- How will they feel when they do so? If so, how long will the feeling last after purchasing (or trying) the product/service for the first time?

Competitive analysis

- Which companies are competing with yours today (and why)?

- Which ones may enter into competition with yours tomorrow if they find out about it now through word-of-mouth advertising; social media networks; friends' recommendations; etc.)

- What specific advantages does each competitor offer over yours currently?

Marketing channels

- Which marketing channel do you intend to leverage to attract new customers?

- What is your estimated marketing budget needed?

- What is the projected cost to acquire a new customer?

- How many of your customers do you instead will return?

Form an LLC in your state!

4. Write Your Operational Plan.

Next, you'll need to build your operational plan. This section describes the type of business you'll be running, and includes the steps involved in your operations.

In it, you should list:

- The equipment and facilities needed

- Who will be involved in the business (employees, contractors)

- Financial requirements for each step

- Milestones & KPIs

- Location of your business

- Zoning & permits required for the business

What equipment, supplies, or permits are needed to run a plastic manufacturing business?

Plastic manufacturing businesses produce a wide range of plastic products, such as containers, packaging materials, and consumer goods. The equipment and supplies needed to run a plastic manufacturing business can vary depending on the specific products produced and the processes used, but may include:

- Raw materials, such as plastic resins and additives, to create the plastic products

- Manufacturing equipment, such as injection molding machines, extruders, and blow molding machines, to shape and form the plastic products

- Quality control equipment, such as gauges and testing devices, to ensure the products meet specifications and standards

- Packaging materials, such as bags, boxes, and pallets, to package and protect the finished products

- Transportation equipment, such as trucks and trailers, to deliver the products to customers

In addition to the equipment and supplies needed to run a plastic manufacturing business, it is important to obtain any necessary permits and licenses that may be required by local regulations. These permits and licenses may vary depending on the location of the business and the specific products produced.

In summary, the equipment, supplies, and permits needed to run a plastic manufacturing business can include raw materials, manufacturing equipment, quality control equipment, packaging materials, and transportation equipment, as well as any necessary licenses and permits.

5. Management & Organization of Your Plastic Manufacturing Business.

The second part of your plastic manufacturing business plan is to develop a management and organization section.

This section will cover all of the following:

- How many employees you need in order to run your plastic manufacturing business. This should include the roles they will play (for example, one person may be responsible for managing administrative duties while another might be in charge of customer service).

- The structure of your management team. The higher-ups like yourself should be able to delegate tasks through lower-level managers who are directly responsible for their given department (inventory and sales, etc.).

- How you’re going to make sure that everyone on board is doing their job well. You’ll want check-ins with employees regularly so they have time to ask questions or voice concerns if needed; this also gives you time to offer support where necessary while staying informed on how things are going within individual departments too!

6. Plastic Manufacturing Business Startup Expenses & Captial Needed.

This section should be broken down by month and year. If you are still in the planning stage of your business, it may be helpful to estimate how much money will be needed each month until you reach profitability.

Typically, expenses for your business can be broken into a few basic categories:

Startup Costs

Startup costs are typically the first expenses you will incur when beginning an enterprise. These include legal fees, accounting expenses, and other costs associated with getting your business off the ground. The amount of money needed to start a plastic manufacturing business varies based on many different variables, but below are a few different types of startup costs for a plastic manufacturing business.

Running & Operating Costs

Running costs refer to ongoing expenses related directly with operating your business over time like electricity bills or salaries paid out each month. These types of expenses will vary greatly depending on multiple variables such as location, team size, utility costs, etc.

Marketing & Sales Expenses

You should include any costs associated with marketing and sales, such as advertising and promotions, website design or maintenance. Also, consider any additional expenses that may be incurred if you decide to launch a new product or service line. For example, if your plastic manufacturing business has an existing website that needs an upgrade in order to sell more products or services, then this should be listed here.

7. Financial Plan & Projections

A financial plan is an important part of any business plan, as it outlines how the business will generate revenue and profit, and how it will use that profit to grow and sustain itself. To devise a financial plan for your plastic manufacturing business, you will need to consider a number of factors, including your start-up costs, operating costs, projected revenue, and expenses.

Here are some steps you can follow to devise a financial plan for your plastic manufacturing business plan:

- Determine your start-up costs: This will include the cost of purchasing or leasing the space where you will operate your business, as well as the cost of buying or leasing any equipment or supplies that you need to start the business.

- Estimate your operating costs: Operating costs will include utilities, such as electricity, gas, and water, as well as labor costs for employees, if any, and the cost of purchasing any materials or supplies that you will need to run your business.

- Project your revenue: To project your revenue, you will need to consider the number of customers you expect to have and the average amount they will spend on each visit. You can use this information to estimate how much money you will make from selling your products or services.

- Estimate your expenses: In addition to your operating costs, you will need to consider other expenses, such as insurance, marketing, and maintenance. You will also need to set aside money for taxes and other fees.

- Create a budget: Once you have estimated your start-up costs, operating costs, revenue, and expenses, you can use this information to create a budget for your business. This will help you to see how much money you will need to start the business, and how much profit you can expect to make.

- Develop a plan for using your profit: Finally, you will need to decide how you will use your profit to grow and sustain your business. This might include investing in new equipment, expanding the business, or saving for a rainy day.

Frequently Asked Questions About Plastic Manufacturing Business Plans:

Why do you need a business plan for a plastic manufacturing business.

A business plan is a document that outlines the goals and objectives of a business, as well as the strategies and tactics that will be used to achieve those goals. It is important to have a business plan for your plastic manufacturing business because it helps to focus the efforts of the company, communicate the business's goals and objectives to potential investors, and provide a roadmap for the business to follow. Additionally, a business plan can be used to help secure funding from investors or lenders, who will want to see that the business has a solid plan in place before they provide funding.

How to write a business plan for your plastic manufacturing business?)

To build a business plan for your plastic manufacturing business, start by researching your industry, competitors, and target market. Use this information to define your business's goals and objectives, as well as the strategies and tactics that you will use to achieve those goals. Next, create a financial plan that outlines your projected income, expenses, and profit. This should include a projected income statement, cash flow statement, and balance sheet. Once you have all of this information, you can use it to create a comprehensive business plan that outlines the goals and objectives of your business, as well as the strategies and tactics that you will use to achieve those goals. A well-written plastic manufacturing business plan contains the following sections: Purpose, Products & Services, Marketing Plan (including Marketing Strategy), Operations/Management Plan (including Operations/Management Strategy), Financial Plan (including Financial Forecasts), and Appendixes.

Can you write a plastic manufacturing business plan yourself?

Yes, you can write a plastic manufacturing business plan yourself. Writing a business plan is a valuable exercise that can help you clarify your business idea, identify potential challenges and opportunities, and develop a roadmap for success. While there are many resources and templates available to help you write a business plan, the process of creating one is ultimately up to you.

Related Business Plans

Home Inventory Business Plan Template & Guidebook

Home Inspection Business Plan Template & Guidebook

Home Decor Business Plan Template & Guidebook

Health And Wellness Business Plan Template & Guidebook

Hauling Business Plan Template & Guidebook

Hardware Business Plan Template & Guidebook

Handyman Business Plan Template & Guidebook

Hair Extension Business Plan Template & Guidebook

Handbag Business Plan Template & Guidebook

I'm Nick, co-founder of newfoundr.com, dedicated to helping aspiring entrepreneurs succeed. As a small business owner with over five years of experience, I have garnered valuable knowledge and insights across a diverse range of industries. My passion for entrepreneurship drives me to share my expertise with aspiring entrepreneurs, empowering them to turn their business dreams into reality.

Through meticulous research and firsthand experience, I uncover the essential steps, software, tools, and costs associated with launching and maintaining a successful business. By demystifying the complexities of entrepreneurship, I provide the guidance and support needed for others to embark on their journey with confidence.

From assessing market viability and formulating business plans to selecting the right technology and navigating the financial landscape, I am dedicated to helping fellow entrepreneurs overcome challenges and unlock their full potential. As a steadfast advocate for small business success, my mission is to pave the way for a new generation of innovative and driven entrepreneurs who are ready to make their mark on the world.

How to launch a new business: Three approaches that work

COVID-19 and its ongoing repercussions have forced business leaders to reevaluate their priorities and strategies. One area where businesses across all regions have accelerated their commitments is around building new businesses. Leading growth businesses in particular have made this strategy a top priority, according to recent McKinsey research .

About the authors

This article was a collaborative effort by Ralf Dreischmeier , Philipp Hillenbrand , Jerome Königsfeld , Ari Libarikian , and Lukas Salomon, representing views from Leap by McKinsey, McKinsey’s business-building practice.

Yet despite the growing enthusiasm for business building, incumbents with good ideas, strong commitments, and big ambitions will frequently run headlong into a big question: How do we actually go about building a business? Getting the answer to this question right is crucial because it shapes the entire operating model of the business-building venture, with significant implications in terms of budget, organization, and strategic direction.

A leading industrial company learned this at a cost. When executives wanted to optimize operations in their factories, they believed setting up a fully independent start-up dedicated to developing new factory concepts was the only way to make it happen. Despite millions of dollars of investment, however, it didn’t work. The start-up struggled to access data and insights, failed to fully grasp the challenges of the core business, and did not attain sufficient support in the parent organization to test and implement changes. This example supports our research, which shows that fewer than a quarter of businesses launched ten years ago are viable large-scale enterprises today .

Figuring out the right approach to business building is especially important now as new opportunities for innovation surface. Prompted by the pandemic, new business-building archetypes have emerged, such as remote service provision, digital retail, and collaboration platforms.

As is true for many complex undertakings, there is no single right approach for launching a new business successfully. In addition, certain strategies will be important no matter which approach a company takes. Joint ventures and alliances, for example, can help to reach scale and enter new markets, and working with partners in ecosystems that, in some cases, include erstwhile competitors can expand offerings, access capabilities, and accelerate scale.

After analyzing more than 200 corporate business builds that we have supported, we have identified three major approaches that have proven successful. While other approaches can certainly work, the three we explore in this article have an established track record and clear conditions for success. The characteristics of each are unique, and so, too, are the criteria and conditions for success (Exhibit 1).

Would you like to learn more about Leap , our business-building practice?

1. internal vc-like incubator.

In this approach, incumbents develop a broad portfolio of ideas, with the goal of producing a few winners that can be successfully commercialized. Teams within the parent organization develop concepts for new businesses and pitch them to a dedicated venture-capital-style board comprising internal and external experts, who select the most promising ones. Successful teams receive milestone-based funding and resources to validate core assumptions and develop a minimum viable product (MVP)—a crucial governance necessity no matter what approach a business chooses (Exhibit 2).

The business has to be vigilant to ensure that the start-up culture “sticks” and that the legacy corporate culture doesn’t slowly start to take over. One way to do that is to assign an experienced business-building coach to each team to build up and nurture an agile test-and-learn culture.

Establishing an incubation approach is particularly suitable for incumbents that have a clear overall sense of the future direction of their business and sector, as well as a strong pipeline of promising early-stage ideas. They may, however, lack initial certainty on what the “winning concepts” will be and how they should be set up for the long term—as an internal division or an external spinout, for example. In our experience, the internal incubation approach works best when the new business is expected to focus on the parent’s core business.

A leading consumer food company achieved great success with this internal incubation approach. After a successful restructuring program, the company’s CEO and board first set a clear vision and ambition that new ventures should primarily benefit the core business and enable significant improvements in the top and bottom lines. Management then invited employees to form small teams that included a team lead and a management sponsor, such as the division head.

Over the course of six weeks, these teams then independently developed more than 100 ideas for new businesses aligned with the overall strategy. All teams scoped out MVPs and pitched their concepts to a newly created internal venture-capital (VC) board that included senior managers, external venture capitalists and technologists, sector experts, and strategic customers.

The VC board then provided initial funding to ten concepts that covered a wide range of applications, including IoT devices, process automation, data platforms, and resourcing marketplaces. Key decision criteria were resources required, path to scale, time to impact, expected overall P&L impact, and unique advantages of the parent company that could be leveraged to build the new businesses. Each initiative was assigned a delivery lead, an experienced business-building coach who helped employees to identify and de-risk the core assumptions first .

Over the course of the next six to ten weeks, these teams built out their MVPs to test core assumptions, such as market demand, required investment, and potential to scale. Those that were successful then approached the VC board and business-unit leadership for additional resources to scale the MVP. Within 16 months, the program to incubate the new businesses became self-funding.

Key success factors

- Adopt a true VC mindset, and kill ideas without clear potential early on in order to cut losses and strengthen the organization’s focus and resources on concepts with high potential.

- Include external experts on your VC board to increase objectivity and add important new perspectives.

- Match venture teams with experienced delivery leads to provide crucial coaching and skill building to test and adapt quickly.

2. Scale-up factory

Frequently, an incumbent organization already has a strong pipeline of new-product and -business concepts that have been validated with first customers and partners. But because it lacks the specialized resources, talent, and expertise required to quickly and successfully scale an entirely new business, promising ideas wither.

A scale-up-factory approach can help address these issues. In this model, the parent sets up a fully owned “factory” that is exclusively dedicated to rapidly scaling promising concepts from the parent’s R&D pipeline into independent businesses. Typically, with this approach, the parent is the first and largest customer of the new businesses. In return, the factory’s new businesses can leverage the parent’s brand, reputation, and customer network. Importantly, providing employees with equity gives them “skin in the game” and helps attract and retain the best digital talent from start-ups and tech firms.

Despite a strong R&D pipeline, new ideas at a leading global energy player frequently did not reach sufficient scale to generate meaningful new revenue streams. To change this, the company used the scale-up-factory approach to address a key business goal: build and scale disruptive technologies and business models from the internal R&D into rapidly growing and revenue-generating businesses.

The new scale-up factory is located in a separate office and staffed with a dedicated team, most of whom were hired to meet the need for specialized skills and a “start-up mindset.” The new company is governed by its own leadership and a dedicated, internal board of directors, rather than by business-unit leaders. While senior group leaders dedicate significant time to strategic decision making and steering toward targets and milestones, they do not get involved in the scale-up factory’s day-to-day decision making.

After two years, the businesses developed by the scale-up factory have scaled to more than 100 employees and have already become a significant revenue-growth motor for the parent company.

- A strong pipeline of “potential blockbuster” ideas within the parent company that have been validated and deemed commercially viable

- Clear funding and governance to establish accountability for each project that has business-unit and factory representation, remove any ambiguity in approvals and funding (such as joint signatures between factory and business unit), and align up front on milestones for the release of further funding

- Strong learning and pattern-recognition processes —the more scale-ups the factory executes, and the better team members become at collecting and codifying learnings, the more efficient the factory’s processes will become (a key insight from our latest research )

Why business building is the new priority for growth

3. ‘clean slate’ business building.

In some cases, executives have identified a big, promising idea for a new business well beyond their organization’s core focus, such as leveraging a disruptive new technology or entering a new industry. In this case, a clean-slate approach works best, with the new business typically fully owned by the incumbent (or jointly owned with external investors) and all talent hired externally.

Similar to the scale-up factory, the new start-up enjoys organizational independence but has greater entrepreneurial latitude. Speed is more important than process perfection in areas such as HR, IT, and procurement. The new business develops its own tech stack, for example, and explores different business models, even working with traditional competitors. It has different compensation and hiring models than the parent company, as well as its own R&D and insights capability to aggressively test completely new markets. Incumbents that have been successful in driving growth via clean-slate business building often start to shift to adapting principles of the scale-up-factory approach described in the previous section.

“Acqui-hiring” talent (that is, hiring an entire team or acquiring a company to access its talent) can be used to turbocharge business builds in any of the three approaches outlined in this article, but it is particularly suitable for accelerating clean-slate builds when internal capabilities are limited. Acqui-hires provide incumbents with immediate access to a well-integrated team with relevant capabilities who can hit the ground running.

Acqui-hiring can work only if the new venture has a strong culture that can quickly and successfully integrate the acqui-hired team. Clear leadership communication and strong alignment of incentives—such as equity awards distributed to all members of the business-building team—are critical to bringing the new team on board and avoiding potential resentment from members from the incumbent organization.

Using a clean-slate approach enabled one of the world’s leading engineering companies to quickly build a highly innovative IoT platform to sell software through an app store. Initial testing had validated the concept, which also had strong support from top management. Given the need to move quickly and lacking the right talent internally, the company set up a new start-up with strong financial backing, a separate office several hundred miles away from parent-company headquarters, and a leadership team hired from leading technology players.

Senior executives from the parent organization narrowed down the catalog of more than 1,000 rules, regulations, and governance processes that new divisions were typically required to implement to only about 50 that were essential. To establish the new business’s neutrality, the company set up a new industry alliance and collaborated with external partners—some of them direct competitors of the parent company—from day one.

To further accelerate this process, the company decided against gradually hiring developers or retraining staff. Instead, it acqui-hired a full development team of more than 30 people from a major software producer. This approach enabled the building of a highly complex digital solution and a thriving ecosystem with dozens of partners at record speed: first sales were generated less than 15 months after the acqui-hire had been completed.

- Strong focus on culture through strong investment in regular team-building activities that are crucial to integrate teams and unite them behind a common goal

- Foundations for an ecosystem of partners built early on by engaging with external partners—even competitors—as soon as the new business is set up, so that the market perceives it as a neutral player; then build out a large-scale ecosystem over time

- A start-up CEO fully committed to the new venture, through incentives (equity, bonus structure, and so on) that are fully tied to the start-up’s fortunes and do not include a “safety net” in the form of guaranteed continued employment with the parent

Business building is increasingly a core strategic pillar for companies operating in a digital world. Selecting the approach that is right for any given business, based on an understanding of the necessary trade-offs, conditions, and criteria for success, is one of the most important decisions incumbents need to make, as it can unlock the opportunity for rapid growth.

Ralf Dreischmeier is a senior partner in McKinsey’s London office; Philipp Hillenbrand is a partner in the Berlin office; Jerome Königsfeld is an associate partner in the Cologne office; and Ari Libarikian is a senior partner in the New York office, where Lukas Salomon is a consultant.

Explore a career with us

Related articles.

Scale or fail: How incumbents can industrialize new-business building

Derisking corporate business launches: Five steps to overcome the most common pitfalls

Innovating from necessity: The business-building imperative in the current crisis

Don't bother with copy and paste.

Get this complete sample business plan as a free text document.

Clothing Manufacturer Business Plan

Start your own clothing manufacturer business plan

New Look, Inc.

Executive summary executive summary is a brief introduction to your business plan. it describes your business, the problem that it solves, your target market, and financial highlights.">, opportunity.

New Look intends to lever up its position as an established retail men’s clothing business now to become a manufacturer of an upscale clothing line targeted at males between the ages of 20 and 40. New Look not only develops the clothing line, but supports it with advertising and promotion campaigns. The company plans to strengthen its partnership with retailers by developing brand awareness. New Look intends to market its line as an alternative to existing clothing lines, and differentiate itself by marketing strategies, exclusiveness, and high brand awareness.

The key message associated with the New Look line is classy, upscale, versatile, and expensive clothing. The company’s promotional plan is diverse and includes a range of marketing communications. In the future, the company hopes to develop lines of accessories for men, women, and children. These accessories will include cologne/perfume, jewelry, eyewear, watches, etc.

New Look not only develops the clothing line, but supports it with advertising and promotion campaigns. The company plans to strengthen its partnership with retailers by developing brand awareness

Our customers are males between the ages of 20 and 40 with a disposable household income. Within this group, there are no color barriers, and customers have diverse backgrounds. The New Look customer is a versatile man who can fit into any environment and is willing to pay a high price for quality clothing.

Competition

Companies are restructuring to create leaner organizations and adopt new technologies. Consolidation has been prevalent in this industry in the past few years, as larger companies gain leverage in market position and cost cutting. In the apparel industry, companies can operate as retailers or manufacturers (wholesalers) or both. For instance, Gap, Inc., a vertical retailer, manufactures and markets their own apparel and accessories. A company like VG Corporation is a manufacturer and sells solely to retail channels. A company like Tommy Hilfiger does both, selling its products to both retailers and consumers (through retail outlets).

We are an alternative to existing clothing lines. We make our own lines which offers exclusivity, your coworkers or other fashion forward friends won’t be wearing the same thing. We are also highly aware of trends and brands, you will be the envy of all your friends because you found us first.

Expectations

The company’s goal is to expand from retail into online, with its own branding, to be sold by the end of the period in other retail stores as well as online.

Financial Highlights by Year

Financing needed.

We are looking to expand our design line so our owner will put in $65,000. Further we are looking for a $115,000 business loan. Both will be paid back by our second year with our already established customer base and relationships

Problem and Solution

Problem worth solving.

The New Look strategy is to expand and grow our existing retail clothing business by aggressively developing and marketing a full range collection of its own brand. It intends to market its line as an alternative to existing clothing lines and differentiate itself through its marketing strategies, exclusiveness, and brand awareness. New Look intends to build on its core portfolio of products and overcome any obstacles by using the company’s expertise in the clothing industry.

The company’s goal over the long term is to make an overwhelming impact on the fashion industry and create a large consumer demand for the product. The company’s goal in the next 2-5 years is to venture into women’s and children’s clothing. It plans to also license a line of cologne and perfume, bedding, underwear, small leather goods, jewelry, and eyewear. According to Standard & Poor’s (S&P’s), women’s apparel accounted for 52% of total apparel sales in 2015.

Nashville Connection

The company has strategic alliances with Music Records and the Entertainment Group. These alliances are valuable to New Look because they provide the needed exposure for its line and the association of its products with celebrities. Celebrities are valuable assets because they receive free clothing for interviews, concerts, and music videos.

Our Solution

New Look clothing line is classy, upscale, versatile, and expensive clothing. Our current customers are males between the ages of 20 and 40. New Look not only develops the clothing line, but supports it with advertising and promotion campaigns. Our customers are the envy of their fashion forward friends. Our prices are in the mid range to upper level in the market, there are more expensive clothes on the market. Our clothes are top notch. This allows our customers to believe they are incredibly smart fashion forward shoppers.

Target Market

Market size & segments.

[note: information here is for illustration purposes only, to serve as a sample business plan. It is not accurate and should not be reused]