New Lab is a platform for scaling frontier technologies to champion the world’s most forward-thinking entrepreneurs and partners with corporate and city stakeholders to catalyze innovation.

Related works

Prototyping / Tech

New Lab is a community of hardware-centric designers, engineers, and entrepreneurs creating the next generation of responsible enterprises through advanced technologies.

In 2011, at the invitation of the Yard, real estate developer David Belt visited Building 128. Inspired by the iron skeleton’s beauty and its historical significance, he and his partner Scott Cohen explored the meaning of “state-of-the-art.” The possibilities, coupled with a desire to provide the city’s design and manufacturing communities with the resources they need to address today’s challenges, led Belt and Cohen to create New Lab.

New Lab’s 84,000-square-foot facility is designed to maximize engagement between innovators in such fields as robotics, artificial intelligence, nanotechnology, energy, and industrial design. Over the last two years, its beta members have launched ventures realizing in excess of $120 million in capitalization. Part of New Lab’s esteemed community: Honeybee Robotics, known for creating robotic systems for Mars missions, and StrongArm Technologies, which designs protective equipment for active workers. Their successes and others are a testament to the New Lab mission: providing a diverse group with access to the shared resources of tools, technology, and each other.

https://newlab.com/

info@newlab.com

Privacy Overview

New Lab at the Brooklyn Navy Yard by Marvel Architects

Brooklyn, new york.

Historically accurate insulated windows and cladding replace the existing envelope to bring the building up to date.

Photo © David Sundberg / ESTO

Photo courtesy Brooklyn Navy Yard Archives

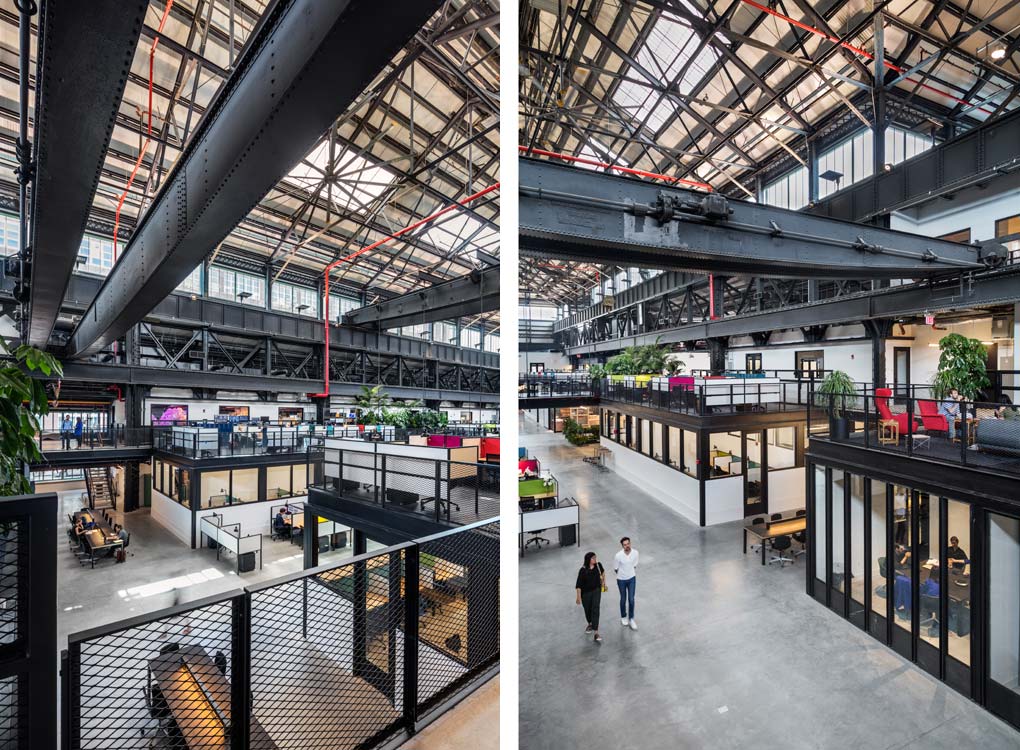

Inside, single-story buildouts—housing studios, meeting rooms, and a makerspace—flank a central corridor and form a mezzanine.

Photo courtesy Brooklyn Navy Yard Archive

Image courtesy Macro Sea

Photo courtesy Macro Sea

Image courtesy Marvel Architects

Architects & Firms

Originally a machine shop for naval equipment, the Brooklyn Navy Yard Building 128, built in 1899, seemed a symbolic fit for modern-day fabrication. Encouraged by historic-restoration grants, loans, and tax credits from government agencies, developer Macro Sea entered into a public-private partnership to convert the building into New Lab, a coworking community with onsite prototyping facilities for frontier-tech entrepreneurs. To bring the structure up to date, Macro Sea tapped New York–based Marvel Architects.

Additional Content: Jump to credits & specifications

The architects stripped the exterior back to the building’s steel skeleton and restored its original historic appearance with insulated metal panels and windows. Inside, the project team preserved structural relics, such as the existing trusses and gantries, while inserting new elements that both refer to the building’s past and meet contemporary programming needs. Single-story enclosures, for example, evoke the material stacks and machining stations that once lined the ground floor’s perimeter. But they also contain key spaces—such as studios and the fabrication lab—while forming the base for a mezzanine floor. A new second level, occupying two sides of the interior, overlooks this mezzanine and the ground floor, with bridges, supported by the gantries, providing access across the interior. These buildouts increased the square footage by 32,000, bringing the total area to 84,000 square feet.

A variety of spaces—from private offices and benching zones to meeting rooms and breakout lounges—helps foster connections among member tenants and ensures that there’s an environment well suited to accommodate numerous work styles and endeavors, whether to develop robotics or advance artificial intelligence. Since its opening in 2016, New Lab has been flourishing, seeing the start-ups and small companies it houses raise upwards of $450 million in capital; some have entered into particularly lucrative deals, such as that of JUMP, a bike-sharing venture whose R&D team called New Lab home from the start, which was acquired by UBER for $250 million.

Back to Good Design Is Good Business 2019

Share This Story

Former RECORD editor Sheila Kim is a Brooklyn-based journalist who writes about commercial and residential architecture, interior design, and products.

Post a comment to this article

Report abusive comment.

Restricted Content

You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days.

Related Articles

Brooklyn's navy yard is home to a manufacturing revival.

Casa Cipriani at the Battery Maritime Building by Marvel and The Office of Thierry W. Despont

AOS Office Renovation by EskewDumezRipple and VergesRome Architects

The latest news and information, #1 source for architectural design, news and products.

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

- AIA New York

- Center for Architecture

- Login --> Login -->

New Lab at the Brooklyn Navy Yard

The intention of the New Lab is to transform Building 128 at the Brooklyn Navy Yard—once a shipbuilding factory—into a high-tech design and prototyping center that fosters creativity and entrepreneurship. New Lab’s ambitions, however, go beyond providing a cutting-edge, collaborative work space for its entrepreneurial occupants. A core goal of the project is to radically revitalize the Brooklyn Navy Yard, turning this once hub for shipbuilding into an epicenter of innovation and growth. To this end, New Lab will have a profound impact on the economic future of the Navy Yard. A variety of classes and educational programs will provide job training for Navy Yard tenants and other high-tech manufacturers, as well as local entrepreneurs who wish to advance their skills. New Lab will also host the best and brightest institutional members, who can utilize its state-of-the-art resources for educational and networking programs in the cutting-edge field of new manufacturing and design.

Project facts

Location Brooklyn, NY

Architect Marvel Architects

Project Team Macro Sea

Category Commercial

AIANY Recognition 2017 AIANY Design Awards

Related Projects

BROWSER UPGRADE RECOMMENDED

- Internet Explorer

- Google Chrome

To revisit this article, visit My Profile, then View saved stories .

- What Is Cinema?

- Newsletters

Inside New Lab, an 84,000-Square-Foot Tech Paradise in Brooklyn

By Emily Jane Fox

Nearly a century ago, Building 128 in the Brooklyn Navy Yard was a hub of military innovation—tens of thousands of workers toiling by the water, building parts for ships used in both World Wars. This month, the building reopens as New Lab, a hub for a different kind of innovation, an 84,000-square-foot space filled with 350 hardware engineers, designers, and entrepreneurs delving into robotics, artificial intelligence, and nanotechnology.

“This was state-of-the-art in manufacturing when it was built, and we started thinking about what the state of the art in manufacturing is now,” said David Belt, a real-estate developer who came to the project with his partner, Scott Cohen, in 2011. They decided that meant a place where 50 companies could rent designated office space under the 70-foot ceilings, snack on grain bowls with other New Lab-ers in tree-dotted, iron-framed, rainbow-colored communal work lounges, and share a full metal-and-wood shop, a 3-D printing lab, and digital manufacturing tools. The combination makes it a Field of Dreams for any designer without the high-tech resources to actually make prototypes meets a Soho House for the more bookishly inclined—a Brooklyn real-estate dream meets a pastiche of Silicon Valley.

There are still touches of the original navy history among the robot prototypes and interactive architectural L.E.D. systems. The giant cranes used to carry ship-engine parts made in the factory remain. Now they hold up a bridge on which engineers in Converse and raw denim eat sour-cherry-yogurt pots from the café downstairs.

Left, a milling machine in the prototype shop; Right, New Lab, a center for engineers, designers, and entrepreneurs under one roof.

See 10 of Los Angeles’s Most Groundbreaking Interior Designs

By Eve Batey

By Kase Wickman

By Bess Levin

Emily Jane Fox

National correspondent.

By signing up you agree to our User Agreement and Privacy Policy & Cookie Statement . This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

By Mary Alice Miller

By Maya Kosoff

By Nick Bilton

By Charlotte Klein

The New Lab: A Repurposed Hub for 21st Century Creative Design

We can adapt defunct space in New York City’s industrial zones into new facilitates suitable for emerging 21st century industries.

By marvel architects.

New Lab is a platform for scaling frontier technologies located within the Brooklyn Navy Yard. Housed within a former industrial shell, the new facility is home to over 100 start-up companies working in advanced technologies in disciplines including robotics, artificial intelligence, urban technology, energy, connected devices, life sciences, and more.

The initial shell and industrial work spaces of Building 128 were constructed by the US Navy in 1899 as a machine shop for producing marine engines and components. Throughout its operating history, the building’s interior layout and working floor were continually modified and reconfigured as new machinery and evolving fabrication methods required facility retooling. With the departure of The Navy in 1966, and the passing of the site to the City of New York, the building sat deteriorated and largely unused through the early 2000s.

In the reconstruction of the facility for present-day use by the New Lab, both the building’s architectural attributes and legacy of fabrication are reflected in the new design. With respect to its intended users, New Lab offers a collaborative workspace and prototyping center in the heart of the Brooklyn Navy Yard. The facility provides professional-quality rapid prototyping equipment, co-working and private office space, and a host of other resources to help entrepreneurs scale frontier technologies.

New Lab’s design incorporates the facets expected of an advanced green research and manufacturing center, while at the same time preserving the structure of the grand historic 1899 hangar that houses it. Consequently, the 84,000SF building is a story of often stark contrasts in harmony – light-filled, visually permeable office pods are positioned against the dramatic backdrop of an industrial armature that is unapologetically visible throughout. In the same vein, secluded spaces for individual or small group work are interspersed with communal work areas and interior plazas over two floors, emphasizing the developer’s intention to strike a balance between the need for privacy and the benefits of collaboration in design and fabrication. A second-story mezzanine is greatly expanded and widened to accommodate additional rooms for small or large group work, connected by a cantilevered catwalk and large bridges suspended from the gantries. These bridges facilitate New Lab’s narrative of coordinated contrasts, allowing the building to maintain its historically vast openness while at the same time generating opportunities for micro-connections between its visiting and resident community.

Brooklyn Navy Yard, New Lab, Location: Brooklyn NY, Architect: Marvel Architects

Members at New Lab develop ideas and test prototypes and products through research, testing and initiatives connecting with business and investment to build products for market, while scaled production occurs off-site. There are currently over 600 individuals that have access to the space (1 job for every 140sf of space) as members of one of New Lab’s 100+ member companies.

In operation since fall of 2016, New Lab serves as a replicable model for establishing a one-of-a-kind center for new manufacturing that is completely independent – not linked to any one corporation, university, or research organization – and a space to cultivate a competitive 21stcentury workforce

Marvel Architects is a solutions-driven design practice with over 30 years of experience providing architectural, planning, community economic development and sustainable development with its award-winning designs at the intersection of public and private space.

Audio Version

See more about, new lab brooklyn: innovative nature of green research and manufacturing center.

Translucent office pods stand in this 82,000 sf building in dramatic contrast to the industrial armature left visible throughout. Communal meeting rooms and interior plazas on both floors emphasize the developer’s intention to create a collaborative design and fabrication center.

A second-story mezzanine is widened to accommodate additional rooms, connected by a steel grate catwalk lit underneath to mark the length of the building. The central axis, preserved as a simple circulation spine, exposes building-through views, a recall of the building’s original factory floor layout.

Once a stunning cathedral of ship manufacture, buildings 128, 123 and 28 of Brooklyn’s famed Navy Yard are being transformed into a high-tech design and prototyping center where designers, manufacturers, fabricators, and institutions will converge to form a hub for innovation and education.

APA MLA Harvard Vancouver Chicago IEEE urbanNext (May 13, 2024) New Lab Brooklyn: Innovative Nature of Green Research and Manufacturing Center . Retrieved from https://urbannext.net/new-lab-brooklyn/ . “ New Lab Brooklyn: Innovative Nature of Green Research and Manufacturing Center. ” urbanNext – May 13, 2024, https://urbannext.net/new-lab-brooklyn/ urbanNext March 19, 2018 New Lab Brooklyn: Innovative Nature of Green Research and Manufacturing Center. , viewed May 13, 2024, https://urbannext.net/new-lab-brooklyn/ > urbanNext – New Lab Brooklyn: Innovative Nature of Green Research and Manufacturing Center. [Internet]. [Accessed May 13, 2024]. Available from: https://urbannext.net/new-lab-brooklyn/ “ New Lab Brooklyn: Innovative Nature of Green Research and Manufacturing Center. ” urbanNext – Accessed May 13, 2024. https://urbannext.net/new-lab-brooklyn/ “ New Lab Brooklyn: Innovative Nature of Green Research and Manufacturing Center. ” urbanNext [Online]. Available: https://urbannext.net/new-lab-brooklyn/ . [Accessed: May 13, 2024]

Related Tags

Related posts, global tags.

- Interviews, debates, conversations on specific topics; also a live stream. Talk

- A magazine article – longer and more thorough, like a paper or a book chapter. Essay

- A visual representation of data, new more complex representations in terms of parameters; interactive. Data

- A project in architecture, landscape, planning. Project

- Photographic feature on cities, landscapes or specific topics. Photographic Atlas of the Cities

Sign up to our newsletter

- Entropic urbanization

- Vegetated envelopes

- Urban Mobility

- Post-extractive practices

- Urban Metabolism

- Advanced Urbanism

- Empowering Women

- Inhabiting Landscape

- Meteorological Urbanism

- Constructing Timber

- Educational Habitats

- Urban Greening

- Textile Architecture

- Self-Sufficiency

- Socio-Ecological Design

- Urban Agriculture

- Modular Design

- Vernacular Design

- Negotiating Borders

- Transport Connections

- Walkable Cities

- Ephemeral Architecture

- Designing for Risk

- Adaptive Reuse

- Algorithmic Design

- Building with Earth

- Dealing with Nature

- Social Inclusion

- Passive Design

- Urban Catalysts

- Watery Territories

- Geographies of Extraction

- Building Living Systems

- Affordable Housing

- Indigenous Practices

- Healthy City

- Cycling Infrastructure

- Thermodynamic Systems

- Kinetic City

- Multiscale Approach

- Recycling & Upcycling

- New Working Habits

- Addressing Vacancy

- Green Transition

- Heat Emergency

- Collective Housing

- Unspoiled Landscape

- Ecologies of the Envelope

- Food Production

- Construction Ecology

- Megablock Urbanism

- On Site Robotics

- The 15-Minute City

- Biotech Architecture

- Out of Wood

- Out of Wood empreses

- Emergency Housing

- Soft Infrastructures

- Sourcing Locally

- Lightweight Envelopes

- Emergent Material Ecologies

- Extraterrestrial

- Alternative Domesticity

- Optimized Construction

- Operative Mapping

- Post-pandemic Design

- Waste Management

- Biophilic Design

- Designing in Extreme Environments

- Sea Level Rise

- Performative Envelopes

- Architecture and Gender

- Inclusionary & Exclusionary Space

- Agency in Architecture

- Biomimetic Architecture

- Micro Living

- Disassembly Strategies

- De-carbonization

- Racial Justice

all formats

Take a look inside a gorgeous inventor's paradise in a remote part of Brooklyn that used to be a deserted, rotted-out machine shop

An inventor's treasure trove lies tucked away in a remote part of Brooklyn.

New Lab , in the Brooklyn Navy Yard, is an oasis for artists, engineers and entrepreneurs, serving as a hub where they can quickly concept, build and test products and ideas.

The two-year-old New Lab, which is the home to over 130 NYC startups today, was once Building 128, a machine shop that created parts for ships used in both World Wars, and had since fallen into disrepair.

New Lab's creators, David Belt and Scott Cohen, turned the 84,000 square-foot facility into a space that would help the entrepreneurs translate their ideas into physical products.

Today, the site houses a 3D printing lab, laser cutters, wood and metal shops, a fabrication shop, an electronics shop, and casting and finishing equipment. This full set of equipment, worth $5 million total, gives creators everything they need to develop a working prototype.

The shops also come staffed with experts and resources that can help creators learn and troubleshoot. In addition to being a one stop shop for product development, New Lab also serves as a platform where startups can collaborate with each other and seek partnerships with larger companies.

Since its inception, New Lab has attracted a wide array of scientists, engineers, and designers working across disciplines like robotics, artificial intelligence, nanotech, energy, biotech, and urban tech.

Take a look inside the immaculately designed New Lab, with innovation showcases around every corner and vibrant colors that pop when contrasted against the building's steel skeleton.

New Lab has four levels. A visual map is available to visitors when they first walk in.

The first floor holds mainly conference rooms, open desks, and event spaces. It also has a few private studios further from the entrance.

Stationed in the center is a tiny, 3D printed 'mini-museum' that explains the theory of perpetual motion.

The cafe is also on the first floor, along with a small kitchenette to the side and a lounge. The colorful cafe counter is fashioned after Maslow's Hierarchy of Needs, which is a model of human motivation referenced frequently in user experience design.

The lounge also has a mini library where members can check out books.

The lounge faces a clear conference room, the back wall of which is lined with a row of rainbow-colored, circular neon lights.

The first thing you see after climbing up the stairs to the second level is a line of mini exhibits.

These mini exhibits showcase a range of subjects from the history of manufacturing, to materials used in manufacturing, to the evolution of technology and engineering.

Along the center of the floor is a long expanse of couches and tables that double as public meeting spaces and cafe-like work spaces.

The space is adorned with colorful furniture and tall plants.

The open space is also a way to showcase the works of New Lab's residents, like this pollution-free, compostable furniture called Mycoform, made by startup Terreform ONE from mushrooms, wood chips, gypsum, oat bran, and other biological materials.

Another example of this is Farmshelf's vertical farming system, which is a way to grow herbs and vegetables without soil. Farmshelf has also deployed three of these units at Grand Central Station.

New Lab has recently teamed up with Johnson & Johnson's JLABS to host the Existential Medicine series, which it describes as the first foray into a potential partnership. The series brings together different members of the innovation and medical community, and New Lab hopes that this can be a platform for addressing critical questions about tech disruption in medicine and how it's trickling down into patient experience.

The first discussion panel of the series included the CEO of Epibone, a startup at JLABS that's using 3D-printing and stem cells to create bones, a Harvard scientist who's creating tiny brain-like organoids in jars to understand neurologic disease, and a Cornell scientist who's growing human blood cells to develop cures for sickle cell anemia.

Source: New Lab

While New Lab is home to startups across various industry sectors, there are around 10 companies that focus on medical technology. We weren't allowed to take pictures inside their labs, but here are a few of them.

OccamzRazor: an AI-neuroscience company trying to find treatments for Parkinson’s Disease by connecting disease knowledge, research, and drug development.

Everbeat: a wrist device with clinical-grade ECG monitoring that can detect heart problems like atrial fibrillation (AF). Class 2 FDA clearance for this wearable device and its accompanying app is expected in early 2018.

Prosper Technologies: a company that using gas infusion across a range of different application including in health and medicine. These include uses in wound care by using increased oxygen flow to create vasodilation and remove bacteria, normabaric oxygen therapy which can treat certain chemical and thermal injuries, and dental and oral care including treatments for periodontal disease, gingivitis, and halitosis.

Inscope Medical: Inscope Medical is a medical device company focused on developing disposable, connected medical devices to optimize airway management in both routine and emergency procedures.

To become a member, entrepreneurs and companies apply online, after which their application is reviewed by the New Lab team as well as experts in the discipline.

Entrepreneurs can choose between multiple types of memberships depending on their needs. Resident Members with long-term (minimum of one-year) leases at New Lab can occupy desks, loft spaces, or studios. Flex Members can access New Lab without a designated workspace and have the option of using the equipment there.

- Main content

Microsoft announces $3.3 billion investment in Wisconsin to spur artificial intelligence innovation and economic growth

May 8, 2024 | Microsoft Source

- Share on Facebook (opens new window)

- Share on LinkedIn (opens new window)

- Share on Twitter (opens new window)

President Joe Biden to join Microsoft for announcement in Mount Pleasant

Editor’s note – May 10, 2024 – This press release was updated to include the full name of National Grid Renewables.

Mount Pleasant, WI – May 8, 2024 – Microsoft today announced a broad investment package designed to strengthen the role of Southeast Wisconsin as a hub for AI-powered economic activity, innovation, and job creation. These investments include $3.3B in cloud computing and AI infrastructure, the creation of the country’s first manufacturing-focused AI co-innovation lab, and an AI skilling initiative to equip more than 100,000 of the state’s residents with essential AI skills. President Joe Biden will join Microsoft President Brad Smith at Gateway Technical College to announce the new investment.

“Wisconsin has a rich and storied legacy of innovation and ingenuity in manufacturing,” said Brad Smith, Vice Chair and President of Microsoft. “We will use the power of AI to help advance the next generation of manufacturing companies, skills and jobs in Wisconsin and across the country. This is what a big company can do to build a strong foundation for every medium, small and start-up company and non-profit everywhere.”

These investments will be rolled out in a four-part strategy designed to create long-term benefits for the state’s economy and job market.

Investing in cloud and AI infrastructure

First, Microsoft will invest $3.3B between now and the end of 2026 to expand its national cloud and AI infrastructure capacity through the development of a state-of-the-art datacenter campus in Mount Pleasant, Wisconsin. The project is expected to bring an influx of 2,300 union construction jobs to the area by 2025, as well as providing long-term employment opportunities over the next several years. This new infrastructure will help enable companies in Wisconsin and across the country to develop, deploy and use the world’s most advanced cloud services and AI applications to grow, modernize and improve their products and enterprises.

Along with building a physical data center, Microsoft will partner with Gateway Technical College to build a Data Center Academy to train and certify more than 1,000 students in five years to work in the new data center and IT sector jobs created in the area.

“This is a watershed moment for Wisconsin and a critical part of our work to build a 21st-century workforce and economy in the Badger State,” said Governor Tony Evers. “Microsoft is a blue-chip corporation that recognizes the strength of Wisconsin’s workers, infrastructure, economy, and our quality of life. Microsoft has chosen to locate and invest here because they know the future is here in Wisconsin.”

Transforming businesses of all sizes in every industry

Second, to help build a thriving regional AI innovation economy, Microsoft will establish a manufacturing focused AI Co-Innovation Lab on the campus of the University of Wisconsin-Milwaukee, the first of its kind in the United States. This lab will connect Wisconsin manufacturers and other companies with Microsoft’s AI experts and developers to design and prototype AI and cloud solutions to improve and accelerate their work and grow their business. This lab will aim to serve 270 Wisconsin companies by 2030, including 135 manufacturing businesses.

The lab will connect with TitletownTech in Green Bay, which was co-founded in 2017 and is funded in part by Microsoft and the Green Bay Packers. Microsoft and the Packers are similarly partnering to help fund the new lab in Milwaukee, which will be staffed in part by Microsoft AI experts and venture experts from TitletownTech.

“The Green Bay Packers are excited to continue our partnership with Microsoft, which we first established with TitletownTech near Lambeau Field, and now will expand and enhance as we collaborate with the AI Co-Innovation Lab,” said Mark Murphy, President and CEO of the Green Bay Packers.

Creating a future-ready workforce

Third, reflecting the critical role of education and training in AI transformation, Microsoft will partner with United Way Wisconsin, United Way Racine, and other community partners, to upskill more than 100,000 people across Wisconsin by 2030 on generative AI. This curriculum will help train residents to use new applications, including Microsoft Copilot, a suite of Microsoft AI services that enhance productivity and creativity.

In addition, Microsoft will work with Gateway Technical College to train and certify 3,000 local AI software developers and provide opportunities for 1,000 local business, civic and government leaders to participate in immersive bootcamps where they can learn how to effectively adopt generative AI into their organizations.

These initiatives underscore Microsoft’s commitment to equipping the workforce with the tools needed for success in an increasingly AI-driven economy.

Reinforcing the community’s central role

And finally, a strong and vibrant economy isn’t possible without a strong and vibrant community. That’s why Microsoft will invest in a series of long-term local education and youth employment programs to support the very community that is supporting us.

In partnership with the Racine Unified School District (RUSD), Microsoft will work with Girls in STEM to expand its program to two additional RUSD middle schools. This expansion will provide access to STEM education for more than 500 middle school-aged girls over the next five years. Working with Racine County, Microsoft will support their Summer Youth Employment Program, matching at least 125 young people (16-18 years old) with local employers to receive soft skills and on the job training annually.

Microsoft will also continue to distribute Equity Through Technology and STEAM Grant Funds to the more than 12,000 people across Racine County engaged in United Way programs. Announced in 2023, these grants help local nonprofits address disparities and support under-resourced communities through the use of technology. Through investment and partnerships with local community organizations, Microsoft will look to contribute to a thriving and growing Southeastern Wisconsin, helping support a community where opportunity is available for everyone.

These announcements build on Wisconsin’s heritage of business innovation and Microsoft’s history of investment in the state. In 2017, Microsoft announced TechSpark , an ecosystem building program to accelerate economic opportunity and job creation now active in all 50 states. Microsoft has invested in the startup ecosystem in Wisconsin through TitletownTech , a partnership with the Green Bay Packers, in computer science and digital skilling with local partners like gener8tor, in digital inclusion with Microsoft Airband , and even local journalism with the Northeast Wisconsin News Lab .

Investing in the environment

Mindful that the expansion of its business must be done in a manner consistent with protecting the environment and expanding affordable energy access for everyone, Microsoft has partnered with National Grid Renewables to build a new 250 megawatt solar project in Wisconsin that will begin operating in 2027. This additional solar power means that by 2027, Microsoft will exceed 4,000 megawatts of flowing into the local grid – an amount of power equivalent to what’s needed to power more than 3 million homes. As part of this work, Microsoft and National Grid Renewables will jointly contribute $20 million over the term of the agreement to a community fund to support under-resourced communities and communities disproportionately impacted by pollution.

We are working to ensure water is managed responsibly. The new datacenter will use recycled water by employing a closed loop cooling system that does not require any additional water after startup. This is a major step towards sustainability and responsible resource management. A relatively small portion of the facility will use water for cooling, but only when the temperature outside is very warm.

For more information, press only:

Microsoft Media Relations, WE Communications, (425) 638-7777, [email protected]

Note to editors: For more information, news and perspectives from Microsoft, please visit Microsoft Source at http://news.microsoft.com/source . Web links, telephone numbers and titles were correct at time of publication but may since have changed. Shareholder and financial information is available at http://www.microsoft.com/en-us/investor .

Related Posts

ServiceNow and Microsoft expand strategic alliance, combining generative AI capabilities to enhance choice and flexibility

Microsoft and LinkedIn release the 2024 Work Trend Index on the state of AI at work

Axel Springer and Microsoft expand partnership across advertising, AI, content and Azure services

The Estée Lauder Companies and Microsoft increase collaboration to power prestige beauty with generative AI

Microsoft earnings press release available on Investor Relations website

- Check us out on RSS

Share this page:

New Climate and Transportation Research Center Established at UC Davis

- by College of Engineering Communications

- May 13, 2024

Today, the U.S. Department of Transportation, or DOT, announced $1.7 million in research funding for a Climate Change and Transportation Research Center at the University of California, Davis.

The new Center for Emissions Reduction, Resiliency, and Climate Equity in Transportation was established through a cooperative agreement with DOT and will support the DOT Climate Change Research and Technology Program as well as the DOT Climate Change Center. It is led by Kari Watkins , an associate professor of civil and environmental engineering and faculty affiliate at the UC Davis Institute of Transportation Studies .

"Tackling the climate crisis and making our infrastructure more resilient has never been more urgent," said U.S. Transportation Secretary Pete Buttigieg. "The funding and the new research center we're announcing today will help develop the solutions we need to reduce carbon pollution from transportation and improve the resiliency of our infrastructure — and help turn those findings into national policy."

The new center will advance research and technologies to support the nation's clean energy goals, accelerate decarbonization of the transportation sector, strengthen the resilience of the nation's transportation infrastructure and address environmental inequities created by the transportation system.

"This investment will spur innovation and support research-backed transportation decisions across the nation," said Dr. Robert C. Hampshire, Deputy Assistant Secretary for Research and Technology and Chief Science Officer.

The center is comprised of partner institutions, including California State University, Long Beach, Texas Southern University, University of California, Riverside, University of Southern California and the University of Vermont, to collectively execute research activities.

Learn more at U.S. DOT

Primary Category

Secondary categories.

Skip to main content

- Agriculture + Food

- Arts + Society

- Business + Economy

- Engineering + Technology

- Environment + Sustainability

- Health + Medicine

- Resources + Energy

- Search news

- UQ responds

UQ hub to enable new range of precision cancer treatments

A range of hyper accurate cancer drugs is in production at a newly opened research and manufacturing hub at The University of Queensland.

The Australian Research Council (ARC) hub for Advanced Manufacture of Targeted Radiopharmaceuticals (AMTAR) is a one-stop-shop connecting biotech firms with expertise and equipment to design, test and deliver groundbreaking precision cancer treatments.

Created through a $5 million ARC grant and more than $10 million in industry funds, the AMTAR hub operates out of UQ’s Australian Institute for Bioengineering and Nanotechnology (AIBN) with support from collaborators across the radiopharmaceutical supply chain.

Professor Kris Thurecht , AIBN Director of Research and Hub leader, said radiopharmaceuticals were an emerging group of drugs designed to spare the body from the harsh effects of cancer treatment.

“The medical technology is still very much in development, but radiopharmaceuticals already represent a multi-billion-dollar industry that will be integral to modern healthcare,” Professor Thurecht said.

“Through AMTAR, we have an opportunity to position Australia as a global leader in this field.”

Professor Thurecht said the non-selective nature of traditional cancer treatments such as chemotherapy and radiotherapy meant healthy cells were damaged.

“But radiopharmaceuticals offer a highly targeted approach, sending radiation equipped proteins directly to the site of cancers and minimising the impact on the body,” he said.

“Radiopharmaceutical science has been around for decades, but it is only through recent advances in scientific infrastructure and instrumentation that we’ve been able to conceive and create commercially viable products.

“AMTAR will be where biotech firms can connect with the scientific expertise and infrastructure needed to develop new drugs and manufacture them at scale.”

ARC Acting Chief Executive Officer Dr Richard Johnson said the AMTAR hub would help unlock the power of radiopharmaceuticals and position Australia at the forefront of a rapidly growing industry.

“The ARC has a proud history of facilitating collaborations that promise wider research benefits and commercial opportunities,” Dr Johnson said.

“By bringing together world-class researchers and industry leaders we are laying the foundations for a rich and lasting radiopharmaceutical manufacturing pipeline.”

AMTAR is a collaboration between UQ, the University of Sydney and multi-national radiopharmaceutical industry partners including Telix, AdvanCell, Starpharma, Clarity Pharmaceuticals, Cyclowest and GlyTherix.

Telix Chief Scientist, Dr Michael Wheatcroft, said it was an exciting partnership.

“AMTAR will accelerate the development and commercialisation of novel radiopharmaceuticals in Australia and the team of high quality industry, academic and research partners will enable the translational science required to bring these innovative new technologies to patients,” Dr Wheatcroft said.

The AMTAR research hub will also feature contributions from The University of Nottingham and University of Tokyo, as well as the Oak Ridge National Laboratory and Memorial Sloan-Kettering Cancer Centre in the US.

Media contacts

AMTAR Business Manager, Shona Osborne [email protected] +61 405 194 690;

AIBN Communications, Alex Druce [email protected] +61 447 305 979 [email protected] .

- Share on Twitter

- Share on Facebook

- Google Plus

Engineering + Technology , Industry Collaboration , Research , Resources + Energy

Experts , Health + Medicine , Research

Health + Medicine , Research , Research Grants

Engineering + Technology , Environment + Sustainability , Research

Health + Medicine , Indigenous Australia

Health + Medicine , Research

Health + Medicine , Research , Science

Experts , Health + Medicine , Research , Sport + Recreation

Recent Headlines

The Conversation

How can we measure the size of australia’s illegal cannabis market – and the billions in taxes that might flow from legalising it, sleep wrinkles are real. here’s how they leave their mark, many people are feeling ecological grief. how can we help those whose work puts them at risk, bagaimana daya tarik fisik memengaruhi penilaian akademis mahasiswa menurut riset, you’ve been ‘volun-told’ to coach junior sport – here’s how to best handle the parents involved.

+61 7 3365 1111

Other Campuses: UQ Gatton , UQ Herston

Maps and Directions

© 2024 The University of Queensland

A Member of

Privacy & Terms of use | Feedback

Authorised by: Director, Office of Marketing and Communications

ABN : 63 942 912 684 CRICOS Provider No: 00025B

Quick Links

- Emergency Contact

Social Media

- Giving to UQ

- Faculties & Divisions

- UQ Contacts

Ph. 3365 3333

New Lab, Research and Manufacturing Center / Marvel Architects

- DBusiness Events

- D500 Soirée

- Party Pictures

- Partner Events

- Photography Request Form

- 30 in Their Thirties

- Company Milestone Profiles

- Detroit 500

- Commercial Real Estate Awards

- Powered by Women

- Faces of DBusiness Law

- Faces of Detroit

- From The Top Lists

- Michigan Makers

- Financial Professionals

- Business Professionals

- Other Professionals

- Restaurants

- Digital Edition

- Purchase Single Issues

- Editorial Calendar

- Newsletters

- Where to Find

- Digital Studio

- Hustle and Muscle Features

- Startup Submissions

- Hustle and Muscle Articles

New $14.5M University of Michigan Center for Naval Research Opens

U.S. Navy Secretary Carlos Del Toro visited the University of Michigan’s $14.5-million Center for Naval Research and Education during graduation week and talked about how the center is helping the U.S. Navy.

“I am incredibly proud of the partnership between the University of Michigan and the Department of the Navy,” says Del Toro. “Michigan is a key teammate in rebuilding our shipbuilding industry and restoring the comprehensive — commercial and naval — power of our nation. I am committed to growing our department’s relationship. We truly would not have the world’s most powerful Navy if not for our nearly 150-year partnership.”

The partnership should help prepare naval engineers for the challenges imposed by rapidly changing marine environments and maritime technology.

To tackle these challenges, the center will build multidisciplinary teams focused on research topics such as:

- Studying how films of algae and bacteria impact vessel performance and how to prevent resulting performance issues.

- Discovering ways to make vessels move more quietly through water.

- Harnessing energy from waves.

- Understanding flow-induced damage to design tougher hull materials.

- Discovering ways to provide more control over vessel drag and maneuverability, such as morphable skin and highly water-repellent surfaces.

The center’s research will focus on building and supporting multidisciplinary teams of U-M faculty, postdoctoral, and student researchers, along with engineers from the U.S. Navy.

“By collaborating with Navy experts, our students and faculty will gain a valuable perspective on emerging maritime challenges and develop new solutions to tackle pressing scientific problems,” says Steve Ceccio, interim dean of U-M’s College of Engineering.

The work by U-M and Navy researchers is expected to help bring discoveries from academic research into maritime technology and operations more quickly.

“If new recruits come in with the skills needed to work on our problems, they can contribute to our projects much faster,” says Joel Hartenberger, a test engineer at the U.S. Naval Surface Warfare Center, Carderock Division in Maryland. “At Michigan, I developed a skill set that allowed me to jump right into some of the Navy’s engineering projects, and I believe the center will extend that opportunity to more young engineers.”

RELATED ARTICLES MORE FROM AUTHOR

Michigan’s largest entrepreneur competition opens 2024 registration, fanuc america in rochester hills debuts world’s first explosion-proof collaborative paint robot, automation alley integr8 playbook focuses on cybersecurity needs in manufacturing, newsletters.

FROM OUR PARTNERS

A casual conversation with mario morrow, sr., what happens when a court rules your contract is ambiguous, discover culinary gems in downtown royal oak: metro detroit’s unsung flavors, eo detroit celebrates inaugural entrepreneur hall of fame inductees, major tenant bankruptcies illustrate importance of early involvement and thoughtful action....

- Terms of Use

- Privacy & Cookies Policy

You are using an outdated browser. Please upgrade your browser to improve your experience. Thanks!

- Associate Vice-President

- News/Events

- Joint Appointments

- Electron Ion Collider

- The Center for Accelerator Science and Education

- The Advanced Energy Center

- Institute for Advanced Computational Science

- Joint Photon Sciences Institute

- SEED Grants

- SBU Parking Permits

- SBU/BNL Shuttle Service

- SEED Grants 2010

Energy Applications of Ionic Liquids: Increasing Research Capabilities for Addressing Environmental Fate and Risk Assessment Needs

Bruce Brownawell School of Marine and Atmospheric Sciences, SBU James Wishart BNL co-PI A.J. Francis BNL collaborator

The proposed Seed Grant would foster new SBU/BNL collaborations and create unique synergies that would better position team members optimize ionic liquid (IL)-based technologies in ways that meet engineering goals, are cost effective, and therefore more sustainable with respect to process performance, energy use, minimization of solvents, and also designed to have minimal environmental impacts of ILs that are released accidentally or during operational use. The proposed seed project couples expertise of the Brownawell lab on the trace level detection and environmental fate of ionic or ionogenic organic compounds to existing research programs at BNL currently tied to applications of ILs which hold great promise for processes related to the production, efficient use, and recycling of energy and energy-related resources. ILs are represented by a vast array of salts typically containing amphiphilic organic cations, paired with inorganic or organic ions. Defined by melting points below 100ºC, the estimated number of ILs is likely in excess of 1 million unique structures that create a diverse portfolio of unique, exciting, and tunable designer solvents in comparison to common solvents in current use.

The proposed activities and research would provide a strong basis for expanding the scope and significance of established multidisciplinary programs at BNL on IL radiation chemistry (Wishart team), task-specific research on the application of ILs in advanced nuclear fuel recycling and treatment (Wishart: DOE sponsored individual PI and multi-institutional research) and research on bioconversion of lignocellulose to ethanol and butanol facilitated by ionic liquid preprocessing (BNL co-PI’s Francis, Wishart and Bell; funded by BNL Laboratory-Directed Research and Development Project). Brownawell’s group brings broad experience in aquatic environmental chemistry, with specific expertise in mass spectrometric detection, aqueous chemistry, and environmental fate of amphiphilic organic cations and anions (surfactants) and their degradates. Brownawell and his students are among a few scientists worldwide that have been working on LC-MS detection and fate of quaternary ammonium compounds, whose structures overlap with, or are structural analogs of, most of the IL cations of current use and research interest. As recently reviewed by Wishart (2009), there are many exciting energy related applications of ILs currently under investigation. This proposal focuses on developing research expertise and collaborations that would allow SBU/BNL to be more responsive to an expected growth in DOE’s interest (and other funding agencies) to invest in IL-based research as options to solve challenging problems associated with both spent nuclear fuel treatment and production of cellulose-based biofuels.

Novel Cancer Homing Peptide for Early Cancer Detection

Jian Coa SOM Division of Cancer Prevention/Chemistry, SBU Nicole Sampson SOM Division of Cancer Prevention/Chemistry, SBU Joanna S. Fowler BNL co-PI

Early diagnosis and prevention of metastasis are major stumbling blocks in the “war against cancer”. Although important advances have been made in the management of solid tumors, the complexity of cancer biology continues to defy technologic advances. In diagnosing and monitoring malignant tumors, physicians classically rely on X-rays to image a space-occupying lesion. However, these images are often late indicators of tumors. Therefore, there is a pressing need for an effective tool for early diagnosis of cancer.

The goal of this "seed grant" is to develop a specific tumor-homing peptide for imaging early cancers and for monitoring cancer progression. Based on our studies of the structure-function relationship of MT1-MMP, a membrane anchored matrix metalloproteinase (MMP), we designed and synthesized peptides which bind to breast cancer cells expressing endogenous or exogenous MT1-MMP. Since MT1-MMP has been demonstrated to be upregulated in invasive human breast cancers even in the early stage, we hypothesize that peptides, which bind to MT1-MMP-expressing cancer cells, will facilitate non-invasive imaging of MT1-MMP expressing tumors in a living subject. We will test our working hypothesis by employing MT1-MMP binding-peptides labeled with the appropriate imaging moiety to identify cancer cells in xenograft tumor models using both optical (fluorescence) and nuclear imaging (PET) approaches. The rationale for this aim is that the development of a molecule-based imaging tool will allow us to detect early cancers with invasive capability. The success of this “seed grant” proposal will facilitate our future NIH grant application aimed at probe optimization and human clinical trials for early diagnosis of cancers and monitoring prognosis of cancers.

This approach is innovative because it utilizes novel peptides specific for MT1-MMP to identify cancer cells by imaging techniques. The proposed research will have significant future implications because development of imaging tools for diagnosis of early/aggressive cancers will significantly improve the outcome of patients with cancer and facilitate translation from bench to bedside. It will also take advantage of the developing Joint Stony Brook University / Brookhaven National Laboratory Bioimaging Institute.

Domains and Interfacial Structure in Ferroelectric Superlattices through Electron Microscopy

Matthew Dawber Physics and Astronomy, SBU Dong Su BNL co-PI

Ferroelectric materials posses a spontaneous polarization which can be switched from one direction to another by an applied electric field. This class of materials also finds use in a myriad of technological applications,with tremendous growth potential in the future as we increasingly turn to smart materials to meet technological challenges. Two particularly relevant applications given contemporary challenges are the possibilities of using ferroelectrics to produce energy, either by use of their piezoelectric properties, or by using their polarization to separate photogenerated electron hole pairs. In this project, we will build up artificially layered ferroelectric superlattices by depositing layers of perovskite oxide materials on top of each other with atomic precision in the lab of Matt Dawber, an assistant professor at Stony Brook. Through our advanced deposition techniques we can produce new materials which have characteristic properties defined by the structure we have imposed on them. We will then perform advanced Transmission Electron Microscopy at the Center for Functional Nanomaterials (CFN) at Brookhaven National Laboratory (BNL), where Dong Su is a tenure track material scientist. Both the PI and co-PI have worked extensively with ferroelectric materials in the past, but are both in the early stage of their efforts on Long Island and this seed grant will serve as the launch pad for a long term program of collaborative research.

Design of Drugs to Target Fatty Acid Binding Proteins (FABPs)

Dale Deutsch Biochemistry and Cell Biology, SBU Huilin Li BNL co-PI Iwao Ojima SBU collaborator

The Principle Investigator from Stony Brook University, Dale Deutsch has recently discovered a novel drug target called the fatty acid binding proteins (FABPs). The action of drugs at this target (inhibitors) would raise the levels of the endogenous “marijuana” like compounds called endocannabinoids leading to remedies for pain, stress and withdrawal from drug abuse. This FABP drug target was the basis of a patent submitted by the technology transfer office at Stony Brook University. The PI here requested seed money to perform pilot experiments to identify inhibitors using techniques of biochemistry (Dale Deutsch in Biochemistry at Stony Brook), of chemistry (Dr. Iwao Ojima in Chemistry at Stony Brook) and X-ray crystallography (Huilin Li at Brookhaven National Laboratories). The requested funding is to initiate new collaborations for work that is not yet funded by any granting agency. This seed money will be used to generate enough data on potential drugs for the FABP targets to lead to a fullfledged NIH grant between the collaborators at Stony Brook University and Brookhaven National Laboratories with the possibility of a subsequent Program Project between Stony Brook University and Brookhaven National Laboratory.

Large Scale Simulations of Quantum Dot Photovoltaic Cells

James Glimm Applied Mathematics and Statistics, SBU James Davenport BNL co-PI Roman Samulyak SBU collaborator Stanley Wong SBU collaborator

The purpose of this proposal is to start a collaboration among the two PIs and two collaborators to investigate the design of photovoltiac solar cells based on quantum dots of semi-conducting materials. The study will be numerical. It will be based on a new DFT code under development at BNL, which has linear scaling. The simulations will be conducted on the NYBlue supercomputer at SB/BNL. The simulations will be compared to the results of an experimental program led by collaborator Stanley Wong, at Stony Brook and at the Center for Functional Nanomaterials at BNL.

The focus of the research will be two-fold. First to participate in the creation of a new, linear scaling DFT simulation code, and secondly to use this code in the modeling of quantum dots, with up to 1000 or perhaps 10,000 atoms. With such problem sizes, simulation of a complete dot will be feasible. On this basis, issues such as impurities and shape effects on the band gap can be explored. These issues are inconvenient to address in a simulation code limited to 100 or so atoms.

It is hoped that this collaboration will provide the basis of a new submission under the leadership of one of us (SSW) to the NSF. We also hope that this work will lead to other funding opportunities, and that the new DFT code will be of interest to other groups at BNL and elsewhere.

Integrated Design and Manufacturing of Cost-Effective & Industrial-Scalable TEG for Vehicle Application

Baosheng Li Mineral Physics Institute, SBU Sanjay Sampath Material Sciences and Chemical Engineering, SBU Jon Longtin Mechanical Engineering, SBU Lei Zuo Mechanical Engineering, SBU

Transportation accounts for over 70 of oil consumption in the United States, yet only 30-35% of the fuel energy is converted into mechanical energy in a typical vehicle, and the rest is lost as waste heat. Significant progress on thermoelectronics (TE) has been made in the past fifteen years, and it has recently been demonstrated that a 5-10% improvement in fuel efficiency can be obtained by converting waste heat from the vehicle exhaust system to electricity using state-of-the-art thermoelectric materials. The exhaust system, however, presents unique challenges for integrating thermoelectric (TE) devices.

Recently a team of SBU faculty (Lei Zuo, Jon Longtin, Sanjay Sampth, Baosheng Li) and a BNL scientist (Qiang Li) won a three-year thermoelectric project from NSF and DOE to develop an integrated solution to fabricate functional TE materials and structures onto exhaust pipes in a rapid, economical, and industrially scalable manner. The proposed approach is based on the recent progress in non-equilibrium material synthesis using rapid quenching, thermal spray of thick films, laser micromachining for feature patterning, and integrated thermal and mechanical design. Unlike traditional module-based design, the central concepts of this project focus on (1) fabricating TE structures directly onto cylindrical exhaust pipes, which will eliminate the tedious process of module assembles, soldering or mechanically attaching, and will result in intrinsically strong interface adhesion between material layers, and (2) to enable high figure-of-merit TE devices that can be economically manufactured from abundant materials using industrial scalable manufacturing processes.

Alexander Orlov Materials Science and Engineering, SBU Michael White BNL co-PI Clive Clayton SBU collaborator Gary Halada SBU collaborator Peter Khalifah SBU collaborator Weiqiang Han BNL collaborator

The efficient conversion of CO2, a greenhouse gas, into hydrocarbons and oxygenates has an enormous potential to address environmental issues and sustainable energy challenges. The methods of reducing carbon dioxide can be classified as: electrochemical, photochemical, photocatalytic and photoelectrochemical. Photocatalytic method is one of the most promising strategies to use for CO2 reduction. It has a potential to convert CO2 into hydrocarbons and alcohols, which can be recycled either for energy production or for chemical synthesis. If successful, this approach can significantly impact energy and environmental areas by using green routes for producing valuable chemicals. It will reduce CO2 emissions by utilizing sustainable sources of energy, such as sunlight. Given the importance of the proposed topic, the results arising from this project are expected to make a significant and lasting impact on sustainable energy generation. This proposal is relevant to Stony Brook and BNL missions of developing the innovative solutions to address the Nation's energy needs in a sustainable manner without harming the environment.

Highly-Efficient Low-Loss Supercapacitors For High-Density In-Grid Energy Storage

Vladimir Samuilov Materials Science and Engineering, SBU Kotaro Sasaki BNL co-PI Gary Halada SBU collaborator Slowa Solovyov BNL collaborator Manisha Rane-Fondacaro University of Albany collaborator

The seed grant funds will establish a long-term collaboration between the Materials Science and Engineering Department at SBU and Condensed Matter Physics and Materials Science and Chemistry Departments of BNL. The proposed work will concentrate on development of a low-loss short term storage supercapacitor-type device. The development effort will utilize extensive experience at the Materials Science and Engineering Department at SBU in synthesis and characterization of thick carbon nanotube films/electrodes with diamond-like coating with well controlled nano-morphology. The project will use advanced characterization facilities at BNL Center for Functional Nanomaterials, National Synchrotron Light Source at BNL and at the Materials Science and Engineering Department SBU. The project will well position BNL- SBU team to respond to the future calls in the energy storage and the electrical grid development.

Development of an in situ reaction chamber to study carbonation mechanism and kinetics of minerals in supercritical carbon dioxide

Donald Weidner Mineral Physics Institute, SBU Toshifumi Sugama BNL co-PI

To meet the increased energy needs of the United States of America development of new and clean energy sources paramount. Geothermal energy is one of the new energy sources that have a large potential to provide energy on a commercial scale. The current limitation of geothermal energy could potentially overcome by using supercritical CO2 instead of water for heat extraction. A major additional advantage of the use of supercritical CO2 for heat extraction is that such a system will combine the extraction of geothermal energy with the storage of the greenhouse gas CO2 in geological formations at the same time. However, the processes in supercritical CO2/water/rock or supercritical CO2/vapor/rock systems at pressure and temperature conditions relevant to geothermal applications and CO2 sequestration are not well understood.

The funding will be used to design and build a suitable environmental cell for in situ investigations of CO2/water/rock or supercritical CO2/vapor/rock systems using synchrotron radiation, and install the cell first at suitable beamlines at NSLS and potentially later at NSLS-II.

Synthesis and Characterization of Bismuth Ferrite Nanostructures for Modeling of Nanodiffraction

Stanislaus Wong Chemistry, SBU Chi-Chang Kao BNL co-PI Ismail Noyan Columbia University collaborator

The goal of this work is to manufacture a series of well-defined single multiferroic bismuth ferrite spherical nanostructures (in the neighborhood of 15 to 350 nm) with known defect profiles. In addition to the intrinsic interest in multiferroic bismuth ferrite spherical nanostructures for device applications, the project will also provide a series of test particles for proof-of-concept experiments for advanced nanodiffraction beamlines, in particular HXN at the National Synchrotron Light Source (NSLS)-II. Our effort will couple with existing investments at Brookhaven National Laboratory (BNL) in the Center for Functional Nanomaterials (CFN), Computer Science Division (ID), and NSLS-II, and encompass researchers from Columbia University and BNL, who are experts in electromagnetic radiation transport, image reconstruction, inverse problem analysis, diffraction physics, and computational physics.

- Call for Proposals

- SEED Grants 2023

- SEED Grants 2022

- SEED Grants 2021

- SEED Grants 2020

- SEED Grants 2019

- SEED Grants 2018

- SEED Grants 2017

- SEED Grants 2016

- SEED Grants 2015

- SEED Grants 2014

- SEED Grants 2013

- SEED Grants 2012

- SEED Grants 2011

- SEED Grants 2009

- SEED Grants 2008

- SEED Grants 2007

- SEED Grants 2006

- SEED Grants 2005

- SEED Grants 2004

- SEED Grants 2003

- SEED Grants 2002

- SEED Grants 2001

- SEED Grants 2000

- SEED Grants 1999

40 Facts About Elektrostal

Written by Lanette Mayes

Modified & Updated: 10 May 2024

Reviewed by Jessica Corbett

Elektrostal is a vibrant city located in the Moscow Oblast region of Russia. With a rich history, stunning architecture, and a thriving community, Elektrostal is a city that has much to offer. Whether you are a history buff, nature enthusiast, or simply curious about different cultures, Elektrostal is sure to captivate you.

This article will provide you with 40 fascinating facts about Elektrostal, giving you a better understanding of why this city is worth exploring. From its origins as an industrial hub to its modern-day charm, we will delve into the various aspects that make Elektrostal a unique and must-visit destination.

So, join us as we uncover the hidden treasures of Elektrostal and discover what makes this city a true gem in the heart of Russia.

Key Takeaways:

- Elektrostal, known as the “Motor City of Russia,” is a vibrant and growing city with a rich industrial history, offering diverse cultural experiences and a strong commitment to environmental sustainability.

- With its convenient location near Moscow, Elektrostal provides a picturesque landscape, vibrant nightlife, and a range of recreational activities, making it an ideal destination for residents and visitors alike.

Known as the “Motor City of Russia.”

Elektrostal, a city located in the Moscow Oblast region of Russia, earned the nickname “Motor City” due to its significant involvement in the automotive industry.

Home to the Elektrostal Metallurgical Plant.

Elektrostal is renowned for its metallurgical plant, which has been producing high-quality steel and alloys since its establishment in 1916.

Boasts a rich industrial heritage.

Elektrostal has a long history of industrial development, contributing to the growth and progress of the region.

Founded in 1916.

The city of Elektrostal was founded in 1916 as a result of the construction of the Elektrostal Metallurgical Plant.

Located approximately 50 kilometers east of Moscow.

Elektrostal is situated in close proximity to the Russian capital, making it easily accessible for both residents and visitors.

Known for its vibrant cultural scene.

Elektrostal is home to several cultural institutions, including museums, theaters, and art galleries that showcase the city’s rich artistic heritage.

A popular destination for nature lovers.

Surrounded by picturesque landscapes and forests, Elektrostal offers ample opportunities for outdoor activities such as hiking, camping, and birdwatching.

Hosts the annual Elektrostal City Day celebrations.

Every year, Elektrostal organizes festive events and activities to celebrate its founding, bringing together residents and visitors in a spirit of unity and joy.

Has a population of approximately 160,000 people.

Elektrostal is home to a diverse and vibrant community of around 160,000 residents, contributing to its dynamic atmosphere.

Boasts excellent education facilities.

The city is known for its well-established educational institutions, providing quality education to students of all ages.

A center for scientific research and innovation.

Elektrostal serves as an important hub for scientific research, particularly in the fields of metallurgy, materials science, and engineering.

Surrounded by picturesque lakes.

The city is blessed with numerous beautiful lakes, offering scenic views and recreational opportunities for locals and visitors alike.

Well-connected transportation system.

Elektrostal benefits from an efficient transportation network, including highways, railways, and public transportation options, ensuring convenient travel within and beyond the city.

Famous for its traditional Russian cuisine.

Food enthusiasts can indulge in authentic Russian dishes at numerous restaurants and cafes scattered throughout Elektrostal.

Home to notable architectural landmarks.

Elektrostal boasts impressive architecture, including the Church of the Transfiguration of the Lord and the Elektrostal Palace of Culture.

Offers a wide range of recreational facilities.

Residents and visitors can enjoy various recreational activities, such as sports complexes, swimming pools, and fitness centers, enhancing the overall quality of life.

Provides a high standard of healthcare.

Elektrostal is equipped with modern medical facilities, ensuring residents have access to quality healthcare services.

Home to the Elektrostal History Museum.

The Elektrostal History Museum showcases the city’s fascinating past through exhibitions and displays.

A hub for sports enthusiasts.

Elektrostal is passionate about sports, with numerous stadiums, arenas, and sports clubs offering opportunities for athletes and spectators.

Celebrates diverse cultural festivals.

Throughout the year, Elektrostal hosts a variety of cultural festivals, celebrating different ethnicities, traditions, and art forms.

Electric power played a significant role in its early development.

Elektrostal owes its name and initial growth to the establishment of electric power stations and the utilization of electricity in the industrial sector.

Boasts a thriving economy.

The city’s strong industrial base, coupled with its strategic location near Moscow, has contributed to Elektrostal’s prosperous economic status.

Houses the Elektrostal Drama Theater.

The Elektrostal Drama Theater is a cultural centerpiece, attracting theater enthusiasts from far and wide.

Popular destination for winter sports.

Elektrostal’s proximity to ski resorts and winter sport facilities makes it a favorite destination for skiing, snowboarding, and other winter activities.

Promotes environmental sustainability.

Elektrostal prioritizes environmental protection and sustainability, implementing initiatives to reduce pollution and preserve natural resources.

Home to renowned educational institutions.

Elektrostal is known for its prestigious schools and universities, offering a wide range of academic programs to students.

Committed to cultural preservation.

The city values its cultural heritage and takes active steps to preserve and promote traditional customs, crafts, and arts.

Hosts an annual International Film Festival.

The Elektrostal International Film Festival attracts filmmakers and cinema enthusiasts from around the world, showcasing a diverse range of films.

Encourages entrepreneurship and innovation.

Elektrostal supports aspiring entrepreneurs and fosters a culture of innovation, providing opportunities for startups and business development.

Offers a range of housing options.

Elektrostal provides diverse housing options, including apartments, houses, and residential complexes, catering to different lifestyles and budgets.

Home to notable sports teams.

Elektrostal is proud of its sports legacy, with several successful sports teams competing at regional and national levels.

Boasts a vibrant nightlife scene.

Residents and visitors can enjoy a lively nightlife in Elektrostal, with numerous bars, clubs, and entertainment venues.

Promotes cultural exchange and international relations.

Elektrostal actively engages in international partnerships, cultural exchanges, and diplomatic collaborations to foster global connections.

Surrounded by beautiful nature reserves.

Nearby nature reserves, such as the Barybino Forest and Luchinskoye Lake, offer opportunities for nature enthusiasts to explore and appreciate the region’s biodiversity.

Commemorates historical events.

The city pays tribute to significant historical events through memorials, monuments, and exhibitions, ensuring the preservation of collective memory.

Promotes sports and youth development.

Elektrostal invests in sports infrastructure and programs to encourage youth participation, health, and physical fitness.

Hosts annual cultural and artistic festivals.

Throughout the year, Elektrostal celebrates its cultural diversity through festivals dedicated to music, dance, art, and theater.

Provides a picturesque landscape for photography enthusiasts.

The city’s scenic beauty, architectural landmarks, and natural surroundings make it a paradise for photographers.

Connects to Moscow via a direct train line.

The convenient train connection between Elektrostal and Moscow makes commuting between the two cities effortless.

A city with a bright future.

Elektrostal continues to grow and develop, aiming to become a model city in terms of infrastructure, sustainability, and quality of life for its residents.

In conclusion, Elektrostal is a fascinating city with a rich history and a vibrant present. From its origins as a center of steel production to its modern-day status as a hub for education and industry, Elektrostal has plenty to offer both residents and visitors. With its beautiful parks, cultural attractions, and proximity to Moscow, there is no shortage of things to see and do in this dynamic city. Whether you’re interested in exploring its historical landmarks, enjoying outdoor activities, or immersing yourself in the local culture, Elektrostal has something for everyone. So, next time you find yourself in the Moscow region, don’t miss the opportunity to discover the hidden gems of Elektrostal.

Q: What is the population of Elektrostal?

A: As of the latest data, the population of Elektrostal is approximately XXXX.

Q: How far is Elektrostal from Moscow?

A: Elektrostal is located approximately XX kilometers away from Moscow.

Q: Are there any famous landmarks in Elektrostal?

A: Yes, Elektrostal is home to several notable landmarks, including XXXX and XXXX.

Q: What industries are prominent in Elektrostal?

A: Elektrostal is known for its steel production industry and is also a center for engineering and manufacturing.

Q: Are there any universities or educational institutions in Elektrostal?

A: Yes, Elektrostal is home to XXXX University and several other educational institutions.

Q: What are some popular outdoor activities in Elektrostal?

A: Elektrostal offers several outdoor activities, such as hiking, cycling, and picnicking in its beautiful parks.

Q: Is Elektrostal well-connected in terms of transportation?

A: Yes, Elektrostal has good transportation links, including trains and buses, making it easily accessible from nearby cities.

Q: Are there any annual events or festivals in Elektrostal?

A: Yes, Elektrostal hosts various events and festivals throughout the year, including XXXX and XXXX.

Elektrostal's fascinating history, vibrant culture, and promising future make it a city worth exploring. For more captivating facts about cities around the world, discover the unique characteristics that define each city . Uncover the hidden gems of Moscow Oblast through our in-depth look at Kolomna. Lastly, dive into the rich industrial heritage of Teesside, a thriving industrial center with its own story to tell.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.

Share this Fact:

- Prospective Students

- Current Students

- Faculty / Staff

- Make a Gift

- Press Releases & Announcements

- Magazine Features

- Sports News

- Deans & Graduate Lists

- Stories in the News

- Media Contacts

Ball State University

- Burris Laboratory School Hosts Record-Breaking International Conference on Collaborative Research in Laboratory Schools

- Press Center

Topics: Burris , Muncie

May 10, 2024

Burris Laboratory School recently set a new standard in collaborative research, hosting the 2024 annual conference of the International Association of Laboratory Schools (IALS).

With unprecedented international attendance, this year’s event, held April 24-26 on the campus of Ball State University, gathered educators, researchers, and professionals from 13 states, one territory, and seven countries spanning four continents, marking a significant milestone in the history of IALS.

"Hosting the IALS conference was a testament to the dedication and collaborative spirit of the Burris community,” said Dr. Abigail Comber, principal and chairperson at Burris. “We are proud to have showcased our commitment to research, innovation, and global engagement."

This year’s conference served as a platform for sharing best practices, fostering cross-cultural understanding, and forging partnerships among educational institutions worldwide. Workshops, presentations, and panel discussions covered a wide range of topics, from inquiry-based learning to the integration of technology in education.

Nicolás Ramos, IALS executive director, emphasized the significance of the conference in advancing global education initiatives.

"The 2024 IALS conference at Burris Laboratory School exceeded all expectations, showcasing the transformative power of collaborative research in laboratory schools,” Mr. Ramos said. “This gathering has not only inspired new ideas but also strengthened our global network of educators committed to educational excellence and innovation.

“We hold conferences at different locations yearly, but this year was different,” Mr. Ramos continued. “Since the planning stages, we knew that the team at Ball State was giving more. We were getting more direction, more spaces to share ideas, more visibility to our member schools, and more benefits to IALS and our membership.”

Dr. Eric Kirkman, principal of the Kilby Laboratory School at North Alabama University and president of IALS, also lauded Burris' dedication to excellence and collaboration.

"Burris Laboratory School has redefined what it means to host a truly inclusive and impactful international conference,” Dr. Kirkman said. “The depth of engagement and the breadth of perspectives represented here demonstrate the power of collaborative research in shaping the future of education."

Students played a central role in the conference, with performances by various musical ensembles and active participation in leading tours, workshop sessions, and presentations. Elementary and middle school students shared their year-long projects during a poster session, showcasing their research alongside educators and professionals.

Reflecting on the conference, Burris students expressed gratitude for the opportunity to engage with international peers and professionals.

"IALS was an amazing opportunity for all involved,” said Adam Stout, a seventh-grade student at Burris. “It provided great exposure to Burris and a stronger sense of community by bringing people together from all over the world."

In addition to fostering student involvement, the conference facilitated meaningful collaborations among educators. Plans for lab-school partnerships emerged, including differentiated math instruction support between Burris and Shevington High School in the United Kingdom, and a teacher exchange program with Thammasat University in Thailand.

The success of the conference was made possible by support from Ball Brothers Foundation , whose grant funding contributed to its planning and execution.

Burris was founded in 1929 by Ball State’s Teachers College . It is now operated and managed by Ball State as a laboratory school for the University. In April, U.S. News & World Report recognized Burris as the 12th-best high school in the state of Indiana in its annual “Best High Schools Ranking.”

For more information about Burris Laboratory School, visit the school website or call 765-285-1131.

Skip to content

- Our Faculty

Educational Programs

News & events, we do health-equity geroscience..